MDO: Machine Directional Orientation

WHAT IS THE MDO PROCESS?

MDO stands for Machine Directional Orientation. While HDPE is relatively good, conventional manufacturing does not always produce the best material performance.

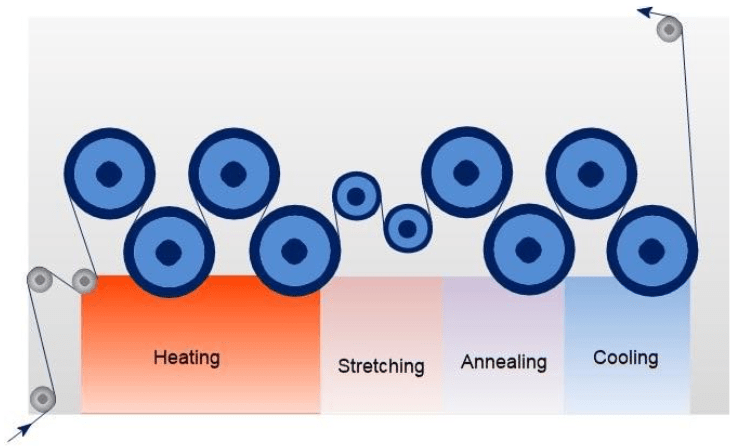

The MDO film orientation process is divided into four phases:

- Heating

- Stretching

- Annealing (heating/curing)

- Cooling

Depending on application – MDO is based on an 8, 10 or 12 roller concept (a lot of friction)

The film is conveyed on heated rollers to obtain the required temperature.

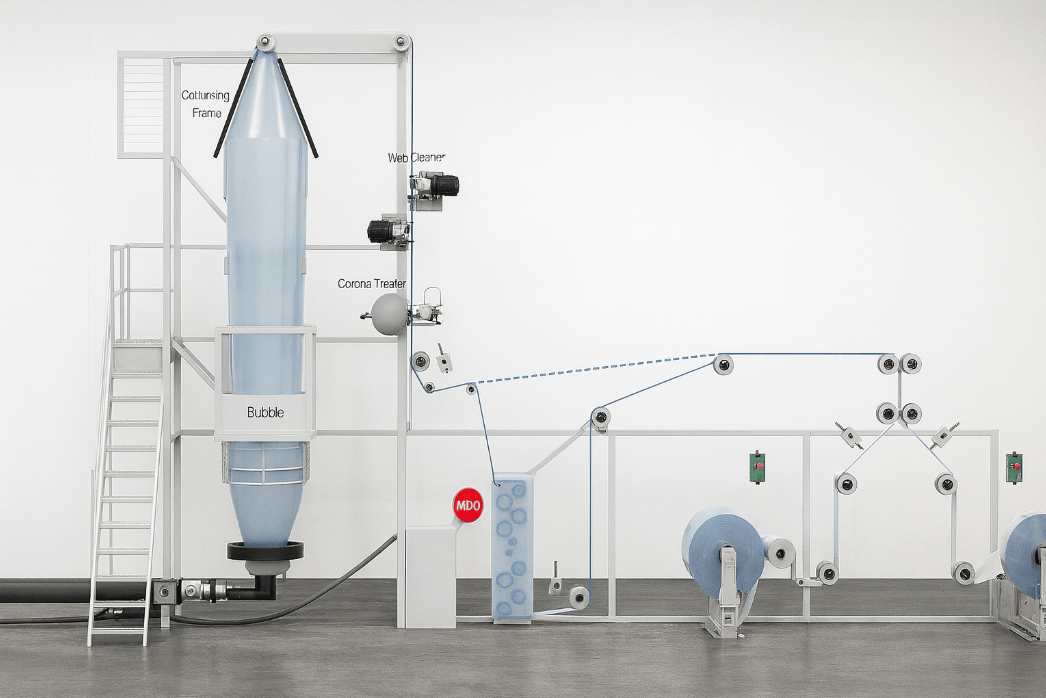

MDO can be in different positions including at the ‘take-off’ position of blown film.

APPLICATION/PROBLEM:

Heat and pressure can result in the production of white flakes or powder on the surface of the material. This can migrate from the material, contaminate the rollers and machinery, resulting in production and quality problems. A recent analysis carried out for a customer with a single ‘traditional’ 1,200mm wide press demonstrated that stoppages and loss of quality due to static build up caused a £13,000 monthly loss in raw materials of ink and paper

EXAMPLE/SOLUTION:

By cleaning the web before the Corona treatment and before the MDO, these important processes are optimized on a clean film surface- leading to better film properties, improved quality, enhanced print finish and increased yields. Meech utilizes the tested VacClean web cleaning system to perform the cleaning of the PE web. In addition to the web cleaning, the PE film will build very high static charges after certain processes, therefore using Meech DC static ionisation is of paramount importance.

Download

- Related Products