SURFACE CLEANERS

Static electricity attracts dust. Our surface cleaners offer an alternative to conventional cleaning methods, which often fail when static electricity is the cause. Use our surface cleaning equipment for a more effective and reliable solution to combat static-attracted dust and particles.

Read more >>

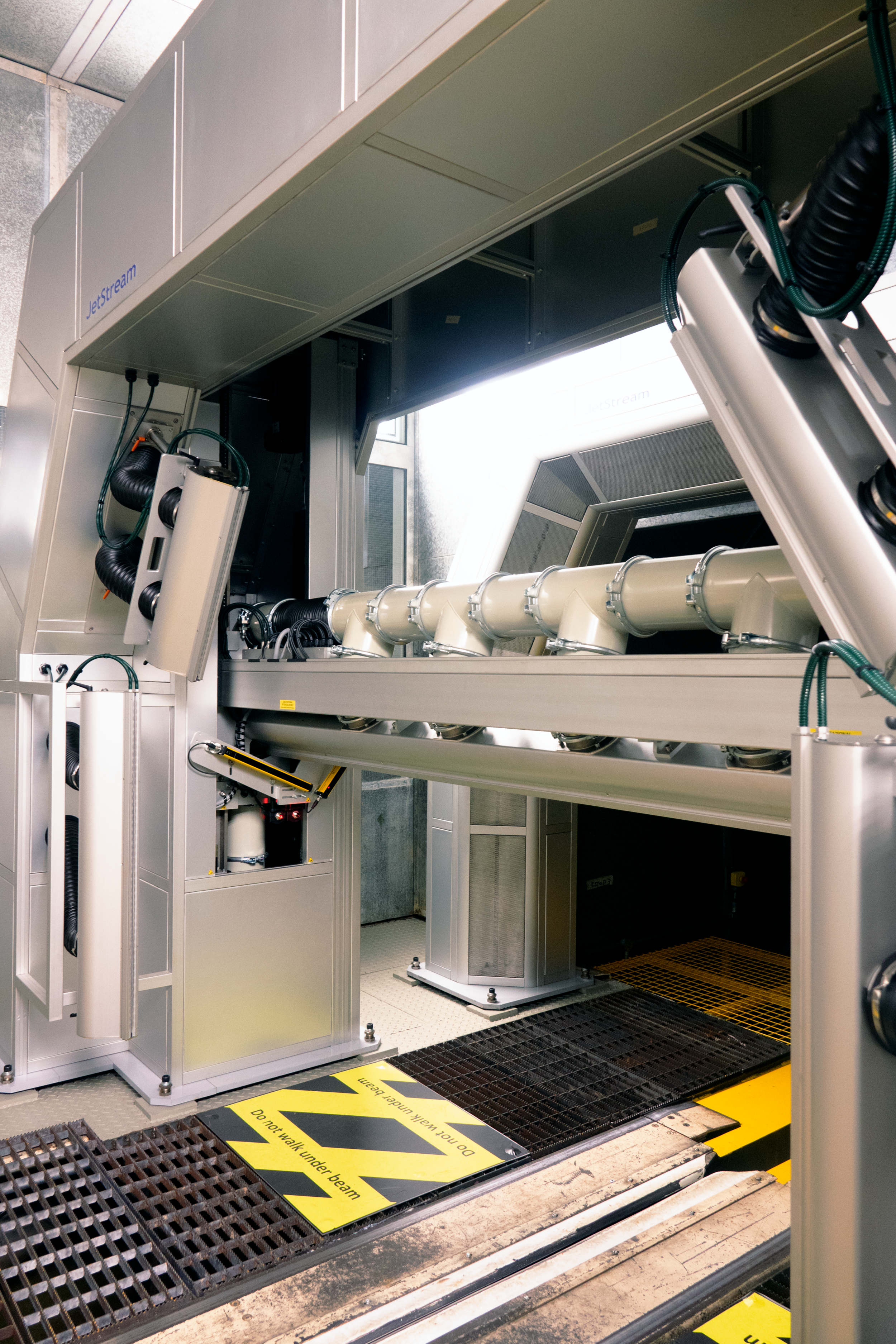

JetStream™ Air Knives

JetStream™ Air Knives use a high-pressure fan unit and a unique “Tear Drop” profile made from hard anodised aluminium and stainless steel to deliver a continuous stream of clean air for effective surface cleaning to remove contamination,...

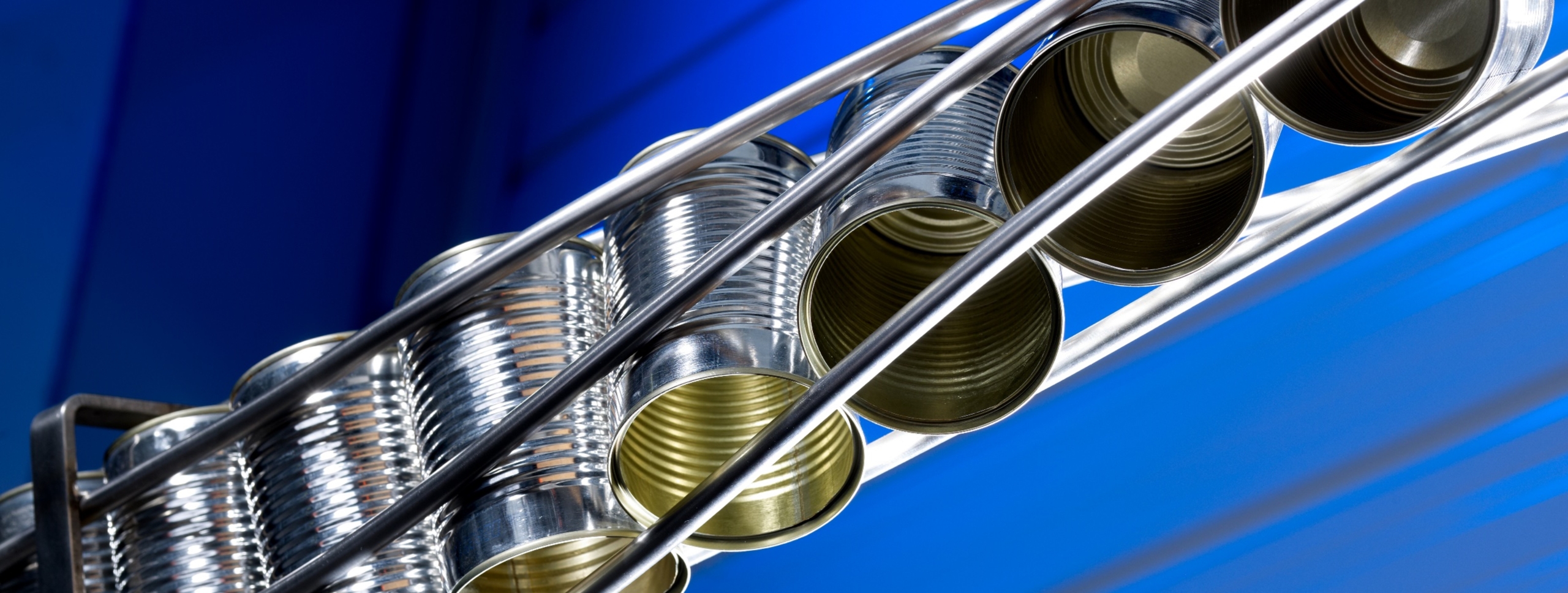

IonRinse™

Ionised, waterless, air rinsing technology has enabled Meech to produce an air rinser that offers significant energy savings and improved sustainability over traditional industrial pre-fill water rinsing systems. Ideal for industrial perform,...

IonWash™

Meech developed IonWash™ in response to a need in the marketplace for fast and consistent cleaning and ionisation of three-dimensional components. The IonWash™ system uses high volume blown air emitted from 16 nozzles and powerful ionisation to...Ionising Blowers

Meech EX Ionising Blowers are designed for use in hazardous areas. All EX Ionising blowers offer the same features and benefits as the non-EX versions along with exceptional performance associated with Meech ionisers.

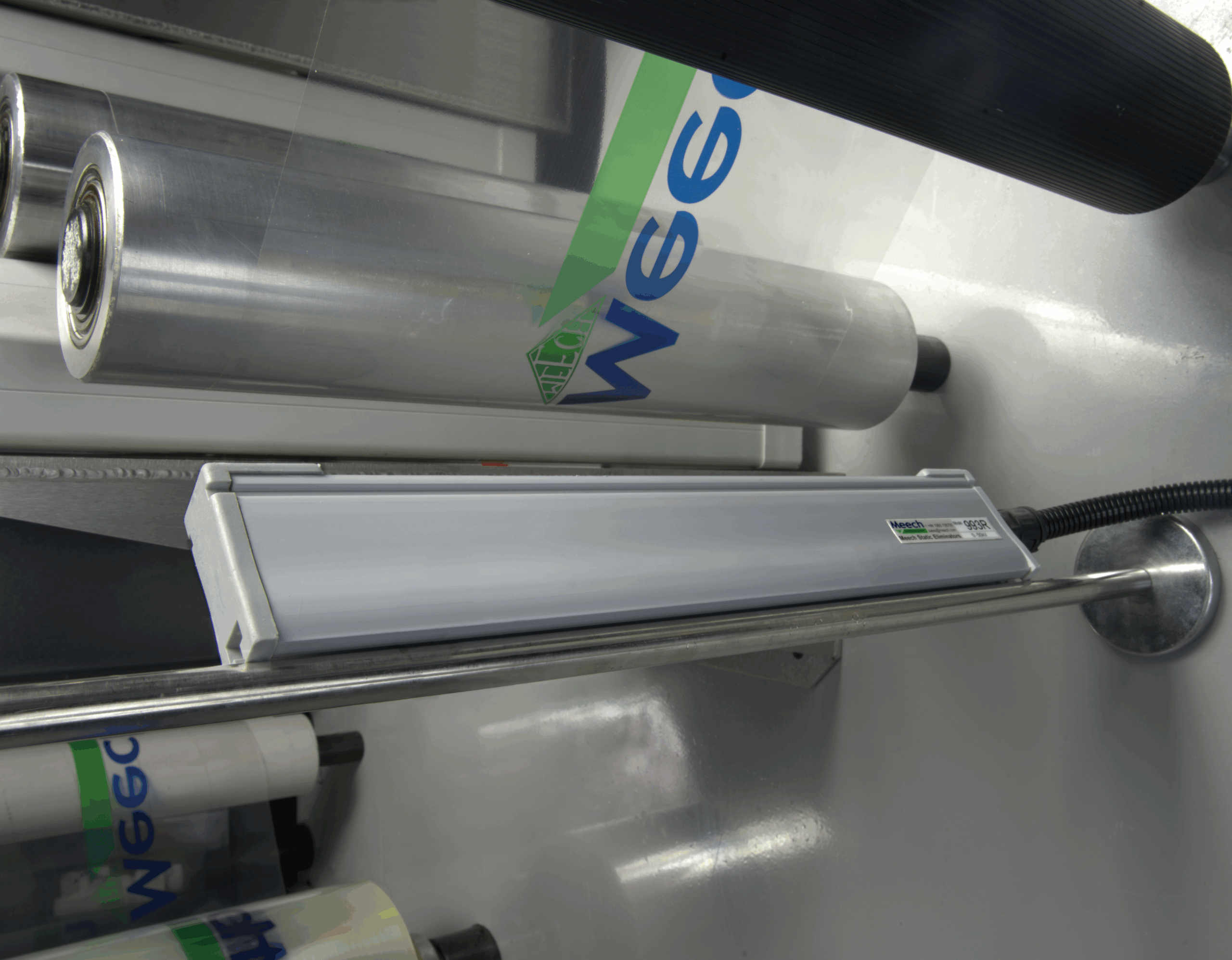

Read more >>STATIC CONTROL

A market leading range of cutting-edge AC or 24V DC static control solutions for static neutralisation, including our revolutionary Hyperion™ range. Static generation systems and IML equipment for controllable temporary adhesion. Accurate static measurement tools to investigate, monitor and measure surface resistivity. Finally, our ATEX static control solutions specifically for hazardous environments.

Read more >>

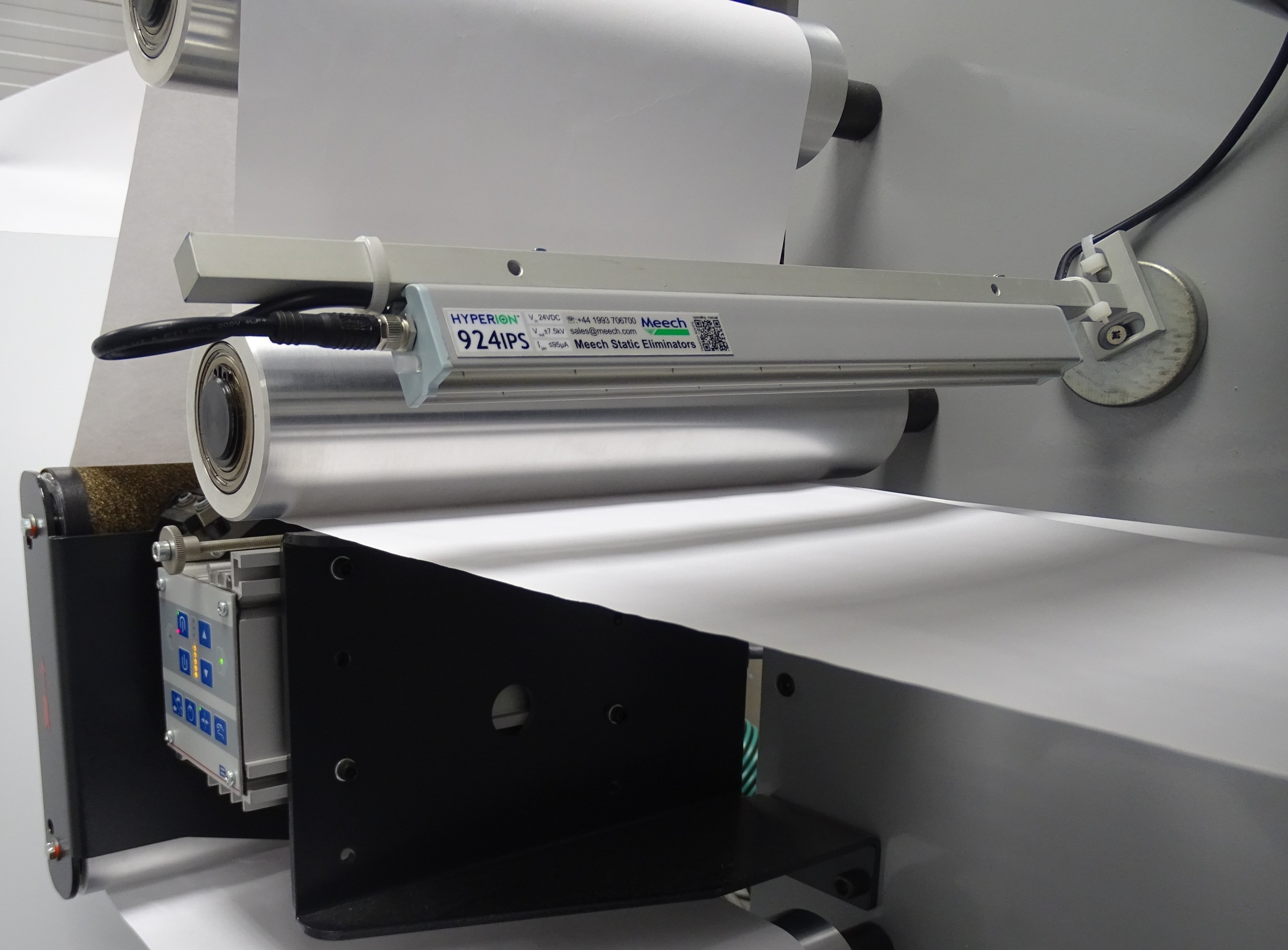

Hyperion™ Range

A market-leading range of the latest, revolutionary, industrial anti-static equipment. Our Hyperion™ range features a number of key characteristics for reliable, high-performance static control. These include Ion Current Monitoring (ICM)...

Measuring Equipment

The range of Meech measuring equipment has been designed to provide accurate readings of electrical charges, the performance (both AC and DC) and the surface resistivity. These hand-held devices are easy to use and vitally important to diagnosing...

AC Ionisation

A market-leading range of AC ionising equipment including high-performance static eliminators and robust power units. Designed to effectively neutralise static charges, our AC ionising equipment is ideal for a wide range of applications.

DC Ionisation

A market-leading range of 24V DC ionising equipment. DC technology allows control of frequency and ion balance, offering flexible static control solutions across a wide range of applications.

Static Generation

Static generation systems including static generators, generator bars and IML equipment for safe and controllable temporary adhesion.

Other Equipment

Passive eliminators providing a simple method for reducing high levels of static. Working on an induction basis, the presence of a passive eliminator causes a redistribution of the electrical charge in the other object. If you have any...WEB CLEANING

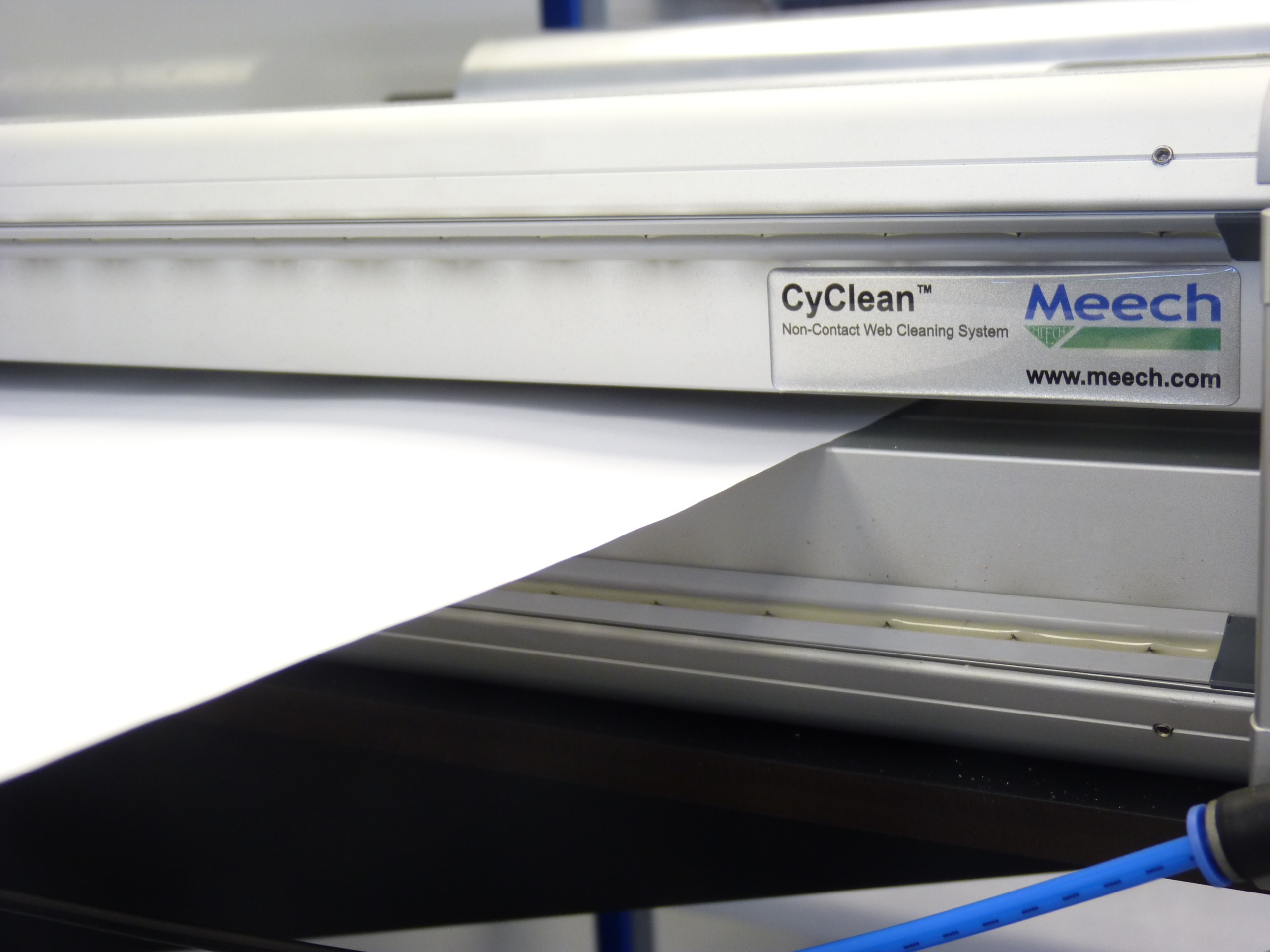

Discover our range of advanced contact and non-contact web cleaning systems, designed to remove contamination from a moving web. Each system is based on a different cleaning principle, allowing us to provide a solution best suited for your specific application. All Meech systems incorporate powerful ionisation as standard, which is crucial for comprehensive contamination removal. Trusted globally across a wide range of industries, our web cleaners optimise production processes and help ensure consistent high-quality results.

Click here to learn how to select the right web cleaner.

Read more >>

Adhesive Rolls

The quality and performance of the adhesive rolls in any elastomer based web cleaning system is vital to achieving the best levels of contamination removal. Meech Adhesive Rolls have been developed to have a high adhesive mass, this results in them...

Non-Contact Web Cleaning

A wide range of non-contact web cleaning systems designed to remove contamination from various applications and materials, capturing particles as small as 0.3 micron. Available in single or double-sided configurations, these systems use airflow...

Contact Web Cleaning

Contact web cleaning systems that remove contamination from a wide variety of materials. They are available in single or double sided configurations, allowing cleaning of one or both sides of the material web. These systems use tacky roller, rotary...AIR TECHNOLOGY

Compressed air systems and industrial energy saving air technology devices with significant noise reduction for energy efficient cooling, conveying and drying.

Compressed air is a safe and reliable power source that is utilised throughout industry. In fact, 70% of UK companies use compressed air in some way. The problem; compressed air is inefficient, expensive and few companies actually look at the way they use compressed air.

Meech manufacture two product ranges both designed to work with a company’s existing compressed air supply. The Air Efficiency Range and the Vortex Cooling Range run solely on compressed air and are used in a wide range of applications within many different industries.

Both ranges are designed to be easy to install, offer fast ROI and noise reductions when compared to traditional compressed air solutions.

Read more >>

Air Efficiency Range

The Meech Air Efficiency range has been developed to reduce energy costs by effectively reducing air consumption. This is done by entraining ambient air into the compressed air flow, which then minimises the need for compressed air. Ultimately this...

Vortex Cooling Range

The Meech Air Cooling range has been designed to provide effective cooling for any number of applications. At the heart of the range is the Vortex Tube. Running solely on compressed air, Meech Vortex Tubes separate the inlet air into two air flows,...EX HAZARDOUS LOCATIONS

Ensuring equipment in hazardous locations is reliable and safe is vital. Hazardous areas may contain flammable gases, vapours and dusts which are ignitable in the air. Meech have developed an ATEX certified range of products specifically for these hazardous EX applications.

Read more >>

EX Surface Cleaners

EX surface cleaners that feature our ATEX certified ionising bars. Developed to provide an effective solution to neutralising static electricity and removing contamination in hazardous locations.

EX Static Control

Meech developed its EX static control range to neutralise static in hazardous areas. A static spark can ignite flammable gases, vapours or dust in the air causing fire, explosion, injury or death.

EX Air Technology

Meech developed its EX air technology range with ATEX certification to cool cabinets & panels in hazardous areas.Air Handling Unit (AHU)

The Meech AHUv3 range is integral to the CyClean, VacClean, RoClean, IonRinse and JetStream systems. The AHUv3 provides positive and vacuum pressure airflows and houses the system filters. It is of robust design and requires minimal maintenance.

With several key features, including full touch-screen control and visual display, digital target vacuum adjustment, automatic vacuum pressure control, remote or local interlock functions and password-protected screen lock, the AHUv3 is a leader in its field. These combined features offer the user advanced operational effectiveness, surpassing the competition.

Read more >>