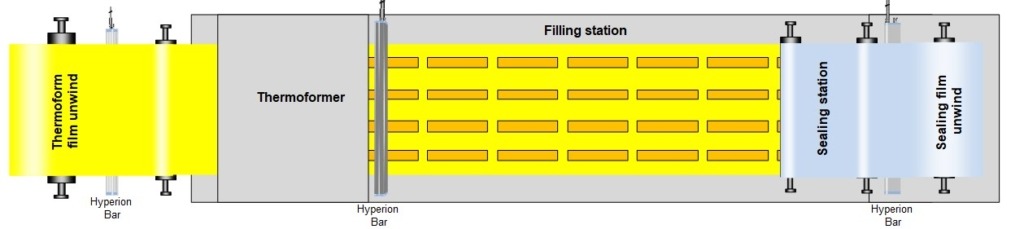

Basic Blister Packing Line

PROBLEM

Static charges generated during unwinding and thermoforming will attract contamination. Manual packing lines are subject to contamination from operators. This may be eyelashes, skin particles or clothing particles.

Controlling the static charges are key to keeping the operation efficient and limiting the contamination risk.

SOLUTION

Neutralising the material at the unwind prevent the attraction of airborne contamination and from the floor or machine frames.

Neutralising static charges of the blister packing after thermoforming will reduce the risk of electrostatic attraction of contamination from operatives.

Neutralising the unwinding sealing film prevents the risk of small products being lifted out of the blister pack and reduce the risk of electrostatic attraction of contamination to the film.

Download