Masterbatch blending

PROBLEM

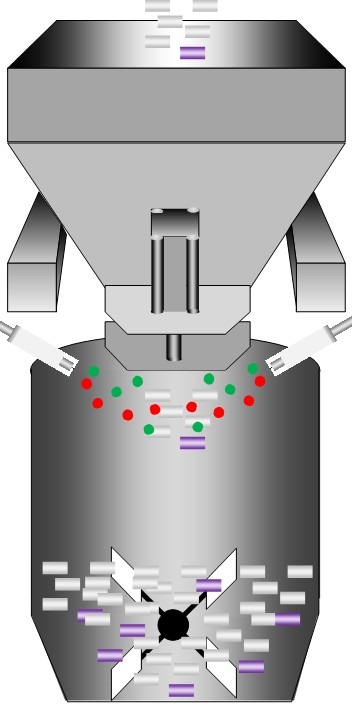

Static charges are generated on the raw material and the masterbatch during blending. This can result in the masterbatch sticking to the blender walls creating weak colour in some mouldings or strong colours in others as lumps of masterbatch drop into the extruder.

Controlling static charges are key to producing quality product to suit the customer need.

SOLUTION

Controlling static charges on the product entering the blender and providing continued neutralisation during the blending process, reduces the risk of colour variance in the final product.

Pulse DC heads are compact but provide ionisation without interfering with the machine process. The DC heads are powered via a remote DC controller.

Download