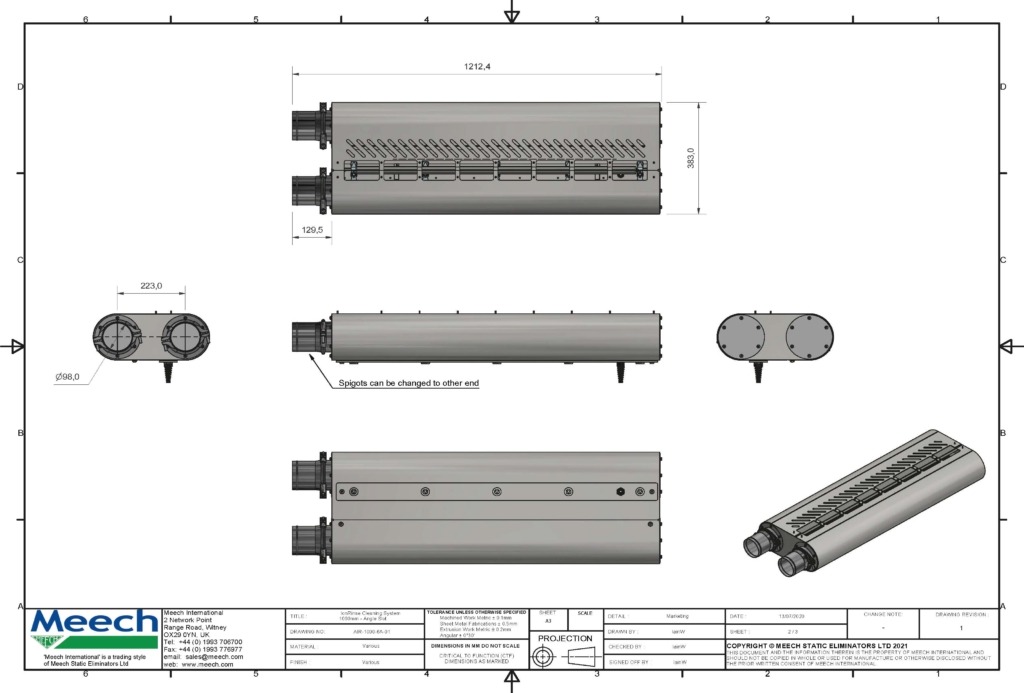

IonRinse™

Product Code: IonRinse™

The IonRinse system combines powerful DC ionisation, a custom designed airflow distributor and high quality inline filtration to provide the ultimate in ionised air rinsing.

The high velocity ionised air exits the IonRinse head unit via the airflow distributor. The control of the airflow coupled with the neutralisation of static charges releases contamination from the container which is extracted to the inline filter unit. The blow and vacuum airflows are provided by the central blow, vacuum and filtration unit.

Cleaning performance is maximised with the container fully inverted (opening facing down) as it travels over the IonRinse head.

In the videos tab, you’ll find an application video courtesy of Traktech SLL, which demonstrates how effective IonRinse is when removing flour from a container.

DownloadFeatures & Benefits

Low maintenance

Low running cost

Easy to maintain and use

Easy to install

Easy to install

Easy to maintain

Low running cost

Low running cost

Easily kept clean

Low running cost

Technical Characteristics

High quality and suitable for use in washdown environments

Customised to suit the container and line speed to ensure maximum performance. Teflon material allows the container to run in contact with the surface

Built in redundancy with stand alone ‘primary’ and ‘reserve’ ionisation systems

Help ensure even airflows along both the air distribution and vacuum slots

Designed to catch the maximum level of removed contamination

Easy maintenance; the ionising bars drop out of the head unit mounted to the access panel

The air inlet and vacuum ducts can be connected at either end of the head unit to suit the installation space available

Ease of installation irrespective of available voltage to frequency

Performance can be optimised to suit the process

Excellent level of filtration; 6m2 of E13 media efficient to 99.99% at 0.3 micron and 6m2 F8 media efficient to 90 – 95% at 0.4 micron

Can be linked to run with the line giving further energy savings

Can suit all installation areas

Ease of installation

Filter status can be linked to line monitoring system

Allows ease of monitoring

Applications

Must Haves

AHUv3 Standard – 3 Pump or 6 Pump

AHUv3 Standard – 3 Pump or 6 Pump

Product Code: AHUv3

The AHUv3 provides the positive pressure and vacuum pressure airflows and houses the system filters. There are 2 models available, a 3 pump unit and a 6 pump unit. For applications where a higher volume capacity is required the 6 pump unit can be used.