JetStream Bottle Drying

PROBLEM

There are 4 areas of concern with this type of packaging machine:

- Wet undersides of cans cause problems when laser or ink jet printing information such as; use by dates, filling dates and bar codes.

- Wet cans cause problems when packaged as ‘multi-packs’ as damage is caused to the packaging.

- On cans that remain wet for a period of time corrosion can occur which could cause rejection of whole deliveries by supermarket customers.

- Wet can surfaces cause Shrink Sleeves to stick and wrinkle causing cans to be rejected by quality control for re-sleeving.

SOLUTION

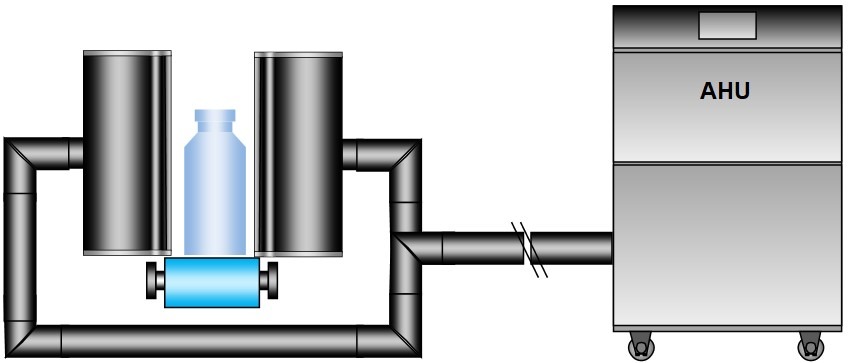

Installation of a Meech JetStream, Air Knife Drying System offers a low running cost solution for the drying of cans and bottles.

High-volume High-pressure air effectively dries the product during conveying. The Meech AHU can be integrated into the process line and remotely controlled by the PLC

Download- Related Products