Selecting the Right Web Cleaner

It is natural that a moving web will attract contamination caused either by the surrounding environment or by the process itself. This contamination can create quality problems ending up in poor quality, customer dissatisfaction and high reject rates, costing valuable resources to any business.

Web cleaning cleans the surface of the web from particle contamination. In order to do this, Meech employs a 3-stage process to ensure effective web cleaning:

- Eliminate the static charges:

A static charge will most likely be present on the web surface. Static charges are typically generated by either separation or friction and until neutralised, a static charge will trap and hold contamination already present on the web to its surface. This also pulls ambient airborne contamination to the web, causing further contamination. Therefore, to achieve excellent cleaning, it is vital that the static charge is removed as part of the cleaning process. All Meech systems incorporate powerful AC or DC ionising bars that will neutralise the static charge, irrespective of the polarity. - Break the boundary layer of air on the web surface to disturb and remove the surface contamination:

Each web cleaner uses a different method for breaking the boundary layer in order to release the contamination. The contamination is then removed away from the web and filtered, so as not to re-enter the production environment. - Successfully isolate and trap all the disturbed contamination:

The Meech CyClean and VacClean systems use the Meech Air Handling Unit (AHUv3). The AHUv3 is exclusively used in Meech systems to provide the airflows and filtration that traps the contaminants. The Meech TakClean system includes a consumable adhesive roll that contamination is transferred to and can later be disposed of.

Meech is the only solution provider to offer 4 unique web cleaning technologies. This means that we are committed to offering you the correct system to suit your application and your budget. Our team of industry experts have extensive experience and have seen all manner of environments and applications, putting Meech in a strong position to deliver the best system for your needs.

How Will I Benefit?

Improved Output Quality

A clean web means a high quality finish, free of surface contamination and imperfections. This is especially important in pharmaceutical and food packaging applications.

Reduced Downtime

Should the web become contaminated, printing presses and other processes will need to be shut down and regularly maintained. This leads to a loss in productivity and therefore, profits.

More Profitable Production

By installing a web cleaner, you can rely on the advanced technology to produce outstanding surface cleaning results. With a clean surface and less downtime, rejects are significantly reduced.

Customer Satisfaction

Due to the improved quality of your finished product, your customer is more likely to be happy with their final product. This means less likelihood of returns that may affect your business reputation.

Repeat Business

With an improved quality output and increased customer satisfaction, your customers are more inclined to place repeat orders as you are a tried and tested supplier.

Which Web Cleaner Is Right For Me? Will Suit My Application? Will Achieve The Best Results?

Contact Cleaning

Our contact cleaners are used in application where contact with the web is not a concern. The cleaners physically make contact with the surface of the web to ensure surface contamination removal.

TakClean incorporates the specially formulated TransTak elastomer contact cleaning rollers and perforated adhesive rolls which, combined, make TakClean the ultimate elastomer based web cleaning machine.

VacClean systems incorporate an enhanced contact cleaning manifold with either an Air Handling Unit (AHU) or vacuum fan unit, depending on the installation environment and web width.

Non-Contact Cleaning

Our non-contact cleaners offer a method of cleaning delicate surfaces where physical contact may cause an issue to the surface quality and finish.

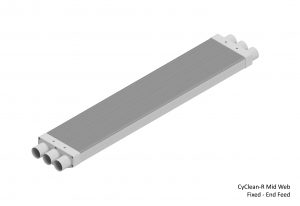

The Meech CyClean™ has been designed in response to increased demand for a compact, high performance, non-contact web cleaning system.

Through the application of advanced computational fluid dynamics, Meech has optimised the cleaning efficiency of CyClean to remove and extract contamination to below 1 micron.

A CyClean system comprises three main components; the cleaning head, active static control and an Air Handling Unit (AHU).

Things To Consider...

The web material is a decisive factor for choosing if your application requires a contact or a non-contact web cleaner. Sensitive materials such as films or LCD screens would require a non-contact web cleaner, which eliminates the risk of surface marking and damage. On the contrary, for materials such as paper, a contact web cleaner can be specified. At this point, you should also think if the material processed on the line regularly changes.

The web speed relates to the thickness of the boundary layer. With a slow-moving web, the boundary layer is thin. As the speed of the web increases, so does the thickness of the boundary layer. If the boundary layer is not removed completely, contamination may remain on the web. Each Meech system uses a different technology to fully break through the boundary layer, ensuring excellent contamination removal.

| Contact Web Cleaning | Non-Contact Web Cleaning | |||

| Web Cleaner | TakClean | VacClean | CyClean | |

| Cleaning Method | Tacky Roller | Vacuum | Vacuum – Blow – Vacuum | |

| Material | Paper, film >10 micron | Any, >50 micron | Any | |

| Web Speed | 250m/min | 1600m/min | 800m/min | |

Meech systems are used to remove many types of dry and unbonded contamination from the web surface. Some common types of contamination on web lines include:

Die-cut chads

Dust – ambient or slitting

Fibres

Hair

Insects

The contamination will vary in size, however, Meech web cleaners are able to effectively clean contaminants down to 0.3 micron.

| Contact Web Cleaning | Non-Contact Web Cleaning | |||

| Web Cleaner | TakClean | VacClean | CyClean | |

| Cleaning Method | Tacky Roller | Vacuum | Vacuum – Blow – Vacuum | |

| Material | Paper, film >10 micron | Any, >50 micron | Any | |

| Contamination Size | >0.5 micron | >5 micron | >0.5 micron | |

| Contamination Level | Low | Very High | High | |

When choosing a web cleaning system, the maximum and minimum web widths that may be passing through the cleaner are important. This will help determine the most suitable system available.

You should consider where you intend to install the web cleaner on your production line and how accessible this space will be for your team. We are aware that space is often limited for many of our customers, that is why we have designed our web cleaning systems to be compact, to easily fit most presses and lines.

Your web tension will help determine which web cleaner is most suitable. For low-tension webs, we have engineered the CyClean-R, which can be positioned on a roller to negate tension issues and still deliver an exceptional clean web surface.