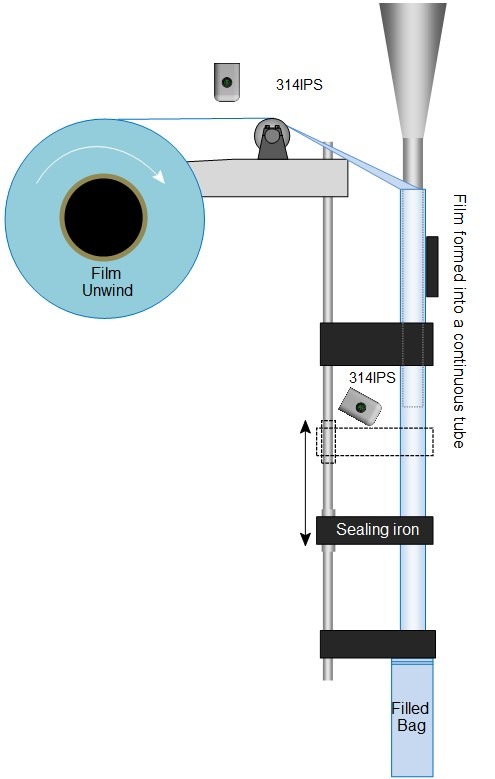

Vertical form filling

Bag Sealing Problems In Vertical Form Fill & Seal Machines

PROBLEM

High static charges are generated when packaging film is fed from a wind off roll. The static charge attracts powder and lightweight dust from the filling products on to the internal film surface. In particular, contaminants get into the seal which prevents effective sealing and is not cosmetically acceptable to the end user/shopper. This prevents proper sealing of the film, resulting in expensive machine down time and scrap product.

SOLUTION

A Model 314IPS bar is positioned prior to the forming tube to eliminate static charges on the film that will become the inside of the tube.

A further 314IPS bar is positioned just before the sealing bars, as per the drawing. Any residual static charge on the film is neutralised, preventing dust from the product attracting to the packaging, allowing full sealing.

- Larger diameters <200mm will require two 314IPS bars

- Metallised films will not benefit from the bars positioned above the sealing bars

The positioning of the bars allows the filling tube to be easily removed or exchanged for different sizes, without the need for demounting.

Download- Related Products