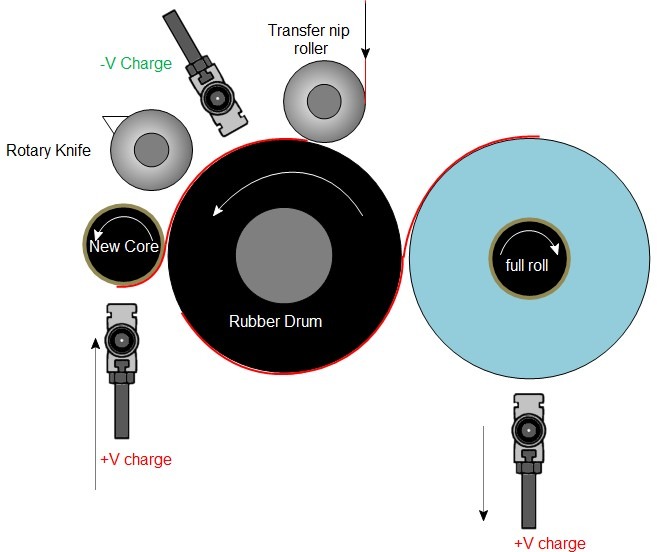

Twin rewind core pinning

PROBLEM

More difficult twin rewind machine designs using a twin core in contact with a hard rubber drive roller, use the adhesive tape solution to allow the web to transfer onto a new core during core transfer. This adds to production costs in both operator time and adhesive tape.

SOLUTION

Using electrostatic attraction charging the material with one polarity and the core with the opposite polarity, once the web is cut the two opposite charges attract to each other allowing the lead end of the web to self-wrap around the core.

This system will require 2 generators with different polarities.

Download- Related Products