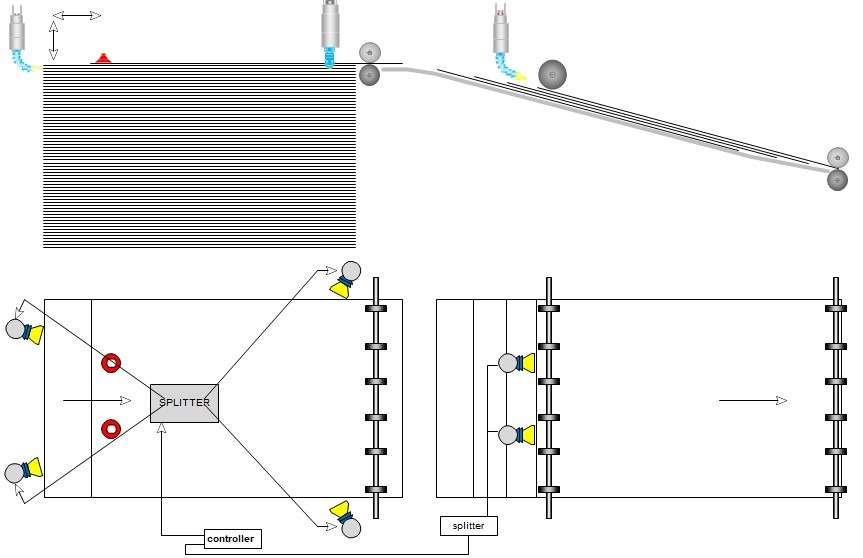

Sheet-feeder

PROBLEM

Feeding sheets from a pallet stack can generate static charges result in:

- Multiple sheets being transferred to the infeed resulting in press stoppages

- The friction between sheets being shingled can regenerate static charges causing the sheets to stick together preventing the jogging alignment required before entering the press.

SOLUTION

Introducing ionised air between the top sheets, neutralises the static charges holding the sheets together, allowing individual sheet entry to the delivery feeder.

Statically charged shingled sheets can be neutralised by introducing ionised air between the first and second sheet awaiting entry into the press, allowing the top sheet to be aligned with the press image print plates.

Note: a compressed air supply will be required if sufficient press pumped air is limited.

Download

- Related Products