Hole detection (Identifying holes in insulative materials)

APPLICATION/PROBLEM:

In the production of insulative materials, identifying weaknesses in the material integrity can be critical to the materials performance. Holes in materials will affect the electrical or airtight properties. Identifying holes as small as <0.3 micron can be achieved using static generation.

EXAMPLE/SOLUTION:

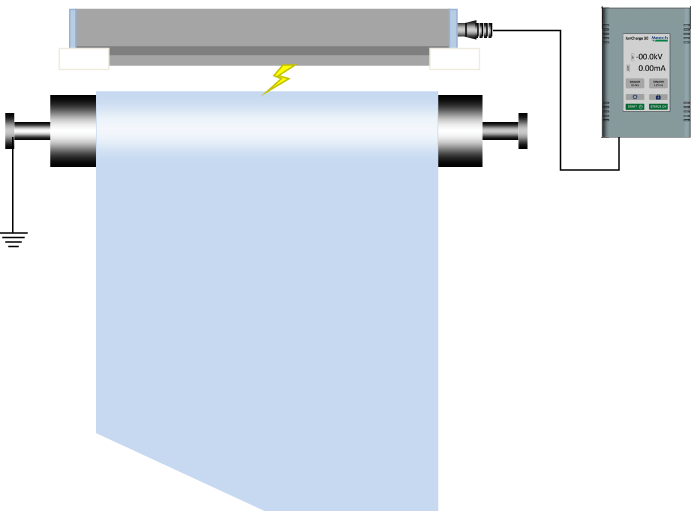

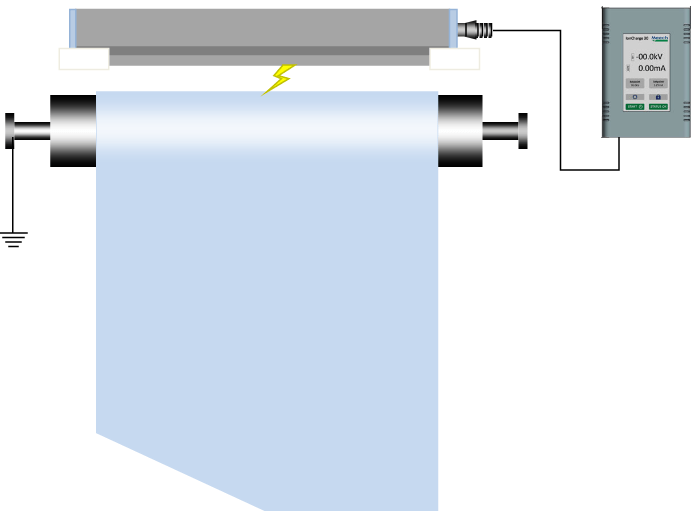

Generating a static surface charge on one side of a material while passing over an earthed roller proves the insulative properties. Any small hole weakens the insulative properties, creating a static discharge through the material to the earthed roller. This creates a spike in current which is registered by the Meech static generator.

The Meech generator when a spark is detected can output a voltage signal to a PLC. This signal can be used by the PLC to control an inkjet printer or similar device to make the material and register for quality purposes the material flaw.

The use of a Meech IC30/ IC50 generator with a spark detection set when used with a non-resistive Meech 993 bar will provide the necessary signal for controlling quality checks during the production process.

When narrower width materials are produced, any emitter pins exposed to the grounded roller need to be masked.

This is achieved using 993-mask strips, designed to slide along the channels on the side of the bar.

Operating distance between the bar and material is recommended to be 20-30mm to minimise the level of static generation required to produce sparks, while minimising web tension issues.

Set the minimum voltage level required to produce consistent spark detection. Leaving the current level set to maximum. This allows the IC generator to auto adjust the current, when ambient humidity levels or material thicknesses are changed.

Download- Related Products