Alignment Of Parisons During Small Bottle Manufacture

Problem

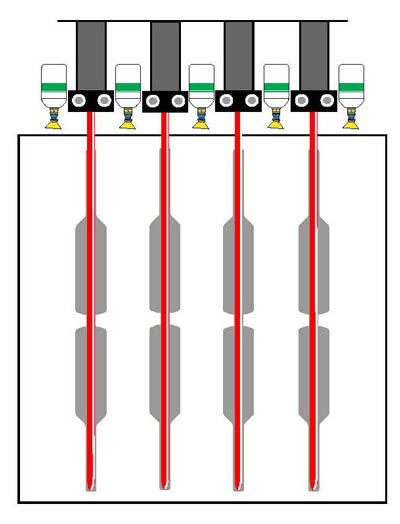

Small extrusion heads positioned close together result in high deflection rates in the parisons and low yield due to pinching by the mould. The limited open area around the extrusion heads and top of the mould causes a proximity earth barrier for delivering ionisation to the parisons.

Solution

Meech recommend installation of 261 Flexi Nozzles to introduce an ionised air flow between the parisons. This prevents the parison deflection without cooling the parison. The compact size of the 261 Nozzle allows it to be positioned above the mould tool, to deliver airflows down the parisons length, limiting contact with the mould tool. This solution has enabled small double cavity containers to be produced, where previous solutions using ionised air curtains and ionising bars did not provide the penetration in between the mould tool.

Download