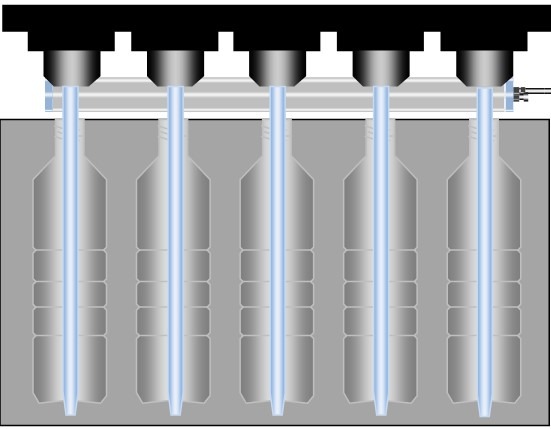

Blow moulding – Parison alignment – limited space

PROBLEM

Where there is limited space between the extrusion heads and the top of the tooling, placing and ionising bar to control the static charges may not be possible.

Product issues will be holes or thin weak walls in the container.

SOLUTION

The use of ionising nozzles positioned between the parisons will deliver ionisation in between the hot parisons without affecting the parison temperature.

Note: compressed air usage needs to be kept to the minimum amount to deliver the ionisation without delivering too much that can create turbulence or increased cooling.

Depending on the number of parisons, splitters and a PDC controller will be required.

Download- Related Products