Board Laminating

Problem

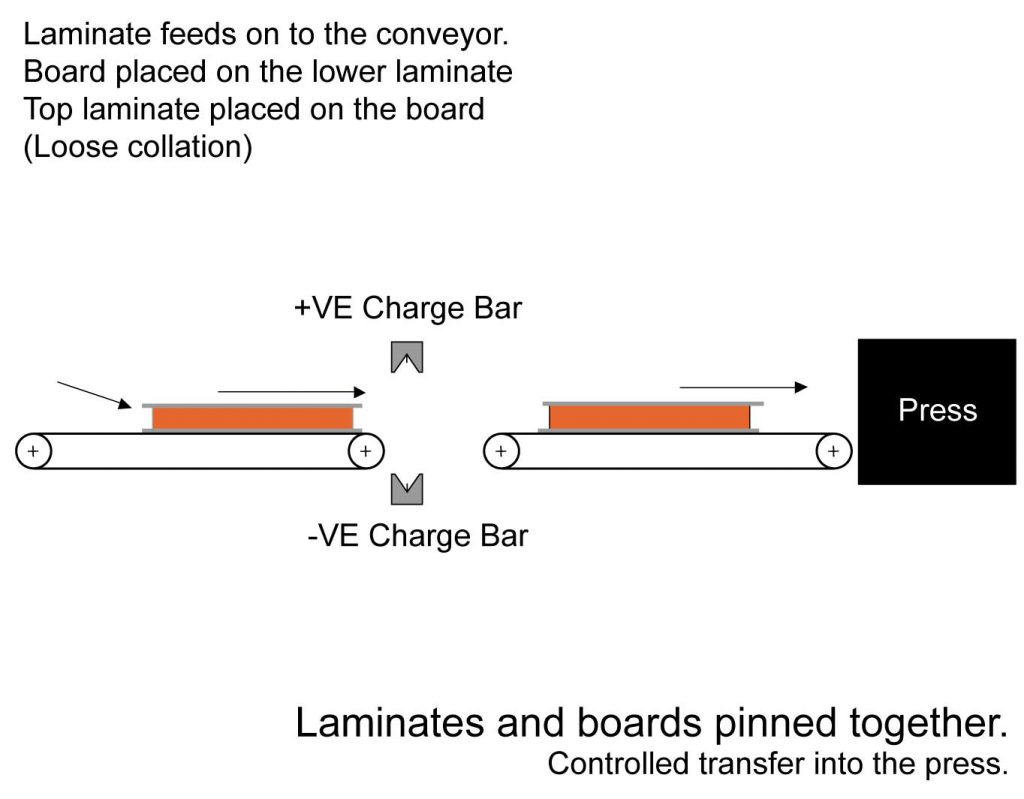

Laminated sheets used for furniture etc, are manufactured by attaching one or two laminates to sheets of man-made board (e.g. MDF). A laminate sheet is fed on to a conveyor and a board is then placed on top. A second laminate sheet (if required) is added, creating a laminate ‘sandwich’. The laminate ‘sandwich’ travels along conveyors to the press where the finished product is formed through heat and pressure. As the laminate travels along the conveyor, the 3 parts can easily move out of alignment leading to product rejection. In the past, spots of glue were used to hold the laminates in place. However it was found that marks could subsequently be seen on the surface where the glue had been applied.

Solution

By installing generator bars opposite each other, the laminate sheets are statically pinned to the board so that the laminate feeds correctly into the press. Special resistor bars allow close installation, which ensures top performance and simultaneously ensures that they do not spark when they ‘see’ each other between sheets.

Download