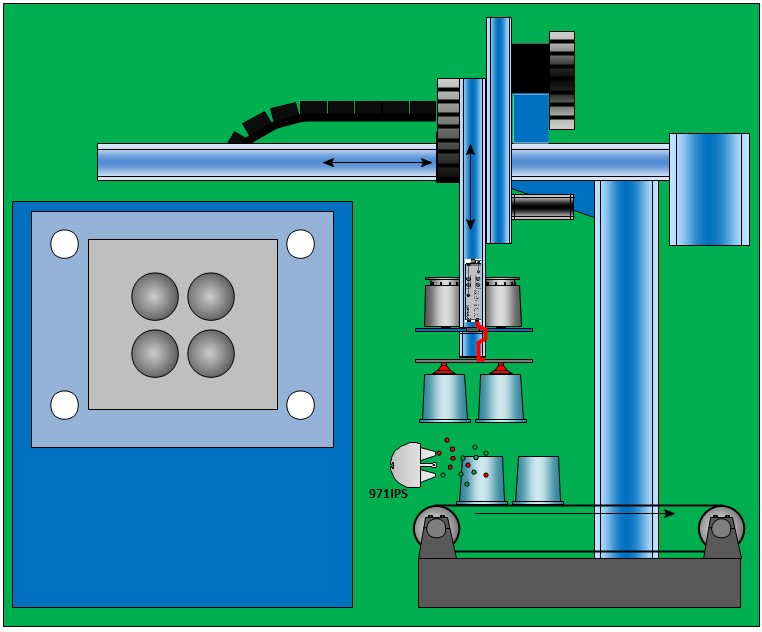

Contamination Control on Injected Moulded Products

Problem

Electrostatic charges generated during the injection moulding process and while cooling of products, attracts contamination from the conveyor and surrounding environment to the products. This problem is exaggerated when In Mould Labelling (IML) is part of the production process.

Solution

Positioning a Meech 971IPS bar at the end of the conveyor near the robot set down, allows the product to pass through the ionising field, neutralising all the surfaces of the product. While the product sits on the conveyor cooling a continuous flow of ions from the bar controls any regeneration of electrostatic charges.

Download