Controlling Fire Risk During Processing Of Sugar

Problem

Highly charged sugar particles falling freely through the air can cause the following problems:

- Contamination of the filling area by highly charged sugar dust

- Painful static shocks to operators

- Attraction of other particles to the charged sugar causing contamination

- Static discharge in a potentially hazardous area. Sugar refineries are renowned as potential dust explosion hotspots.

Solution

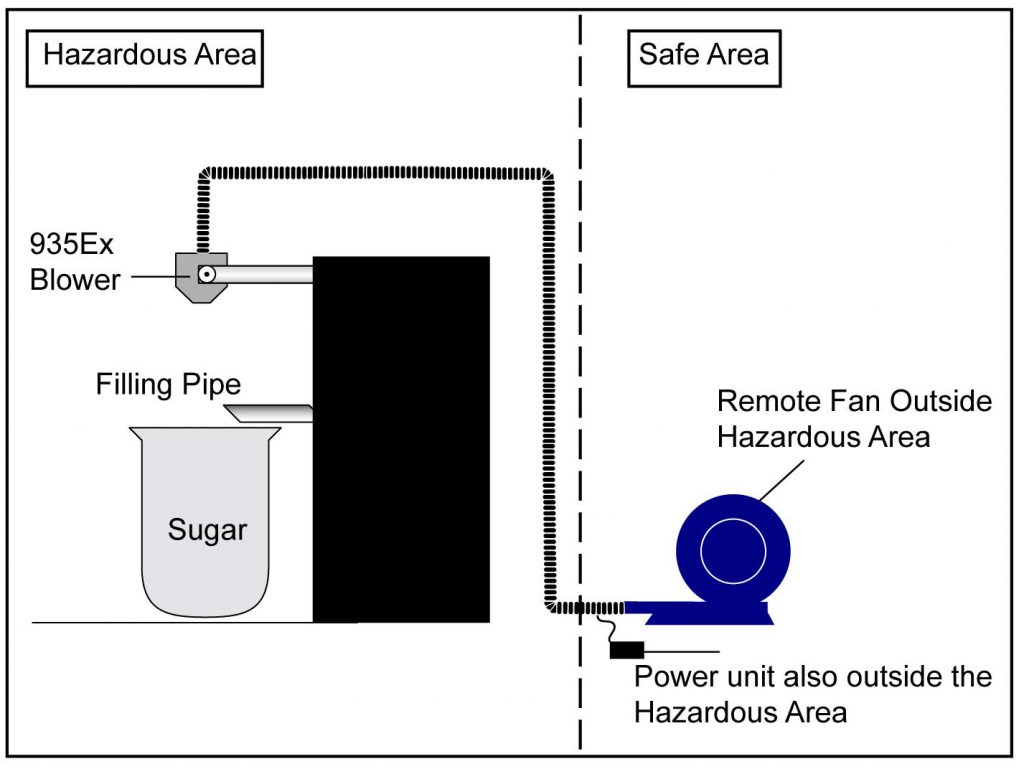

Position a Model 935EX Hazardous Area blower above the filling station. This will prevent the build up of static charges and thus solves the problems outlined above.

NOTE: EX POWER UNITS AND AIR SUPPLY FANS MUST BE SITUATED OUTSIDE THE HAZARDOUS AREA.

Model 935EX Blowers are designed and certified for use in hazardous areas (Zones I and II). BASEEFA Certification to EXs IIA T6 (SFA3009:1985).

Download- Related Products