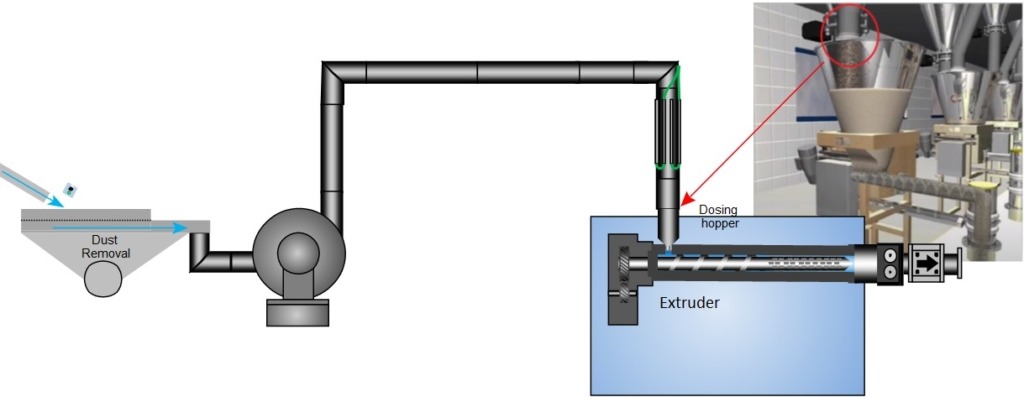

Dust removal – hopper – flowtube

PROBLEM

Discoloration in injection moulding is caused by contamination of equipment not properly cleaned. Cleaning of the machine during colour changes is time consuming adding to costs.

Static charges on dust and granules will overpower vibration and airflows used in separators.

SOLUTION

Introducing ionisation into the process as the granules are dispensed onto the sieve, neutralises the static charges, allowing the sieve to separate the duct from the granules before deliver to the moulding machine.

Controlling static charges on the granules and masterbatch entering the dosing hopper, prevents the masterbatch from sticking to the hopper walls, which will create errors on colour depth.

Download