IML Decoration Of Plastic Moulds Using Static Pinning

Problem

During in-mould labelling processes, the label must be placed and held in an accurate position inside the mould tool. This can be complicated and unreliable using tabs or recesses. Movement of the label will lead to the product being rejected.

Solution

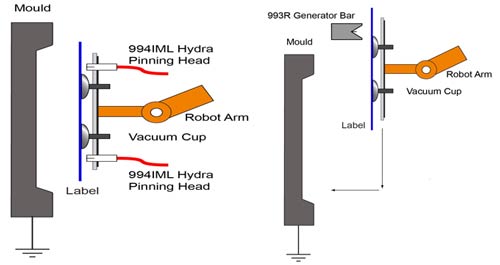

Pinning the label in-situ using static electricity, avoids complicated design issues and provides an excellent temporary bond to fix the label in place during the moulding process. The label is picked up by the robot arm and then it is either passed over a static charging bar and placed into the tool, or is moved into the tool and ‘pinned’ directly on to the surface of the tool. Both these processes can also be manual. Once the label is stuck to the tool surface the robot arm retracts, the mould closes and plastic is injected to form a plastic container complete with label.

Download- Related Products