Label stacking & conveying

PROBLEM

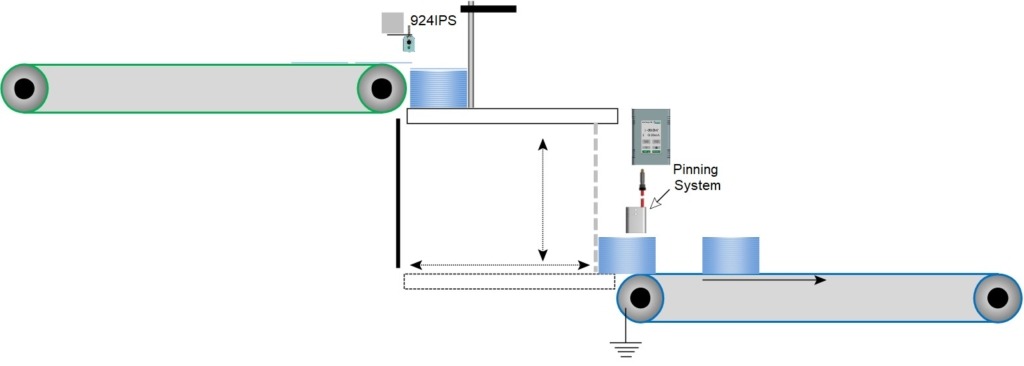

Die cut labels exit conveyor onto the stack. When the stack is complete, they transfer to a second conveyor. During transfer the labels slip causing the stack to fall over. This can result is excess work and potential label edge damage when restacking.

SOLUTION

Neutralising the static charges on the labels as they collate allows the labels to stack properly.

During transfer to the second conveyor, a static charge is applied to the top of the label stack, locking the labels together making pick up and packing easier.

Download