Laminating Formica worktops

PROBLEM

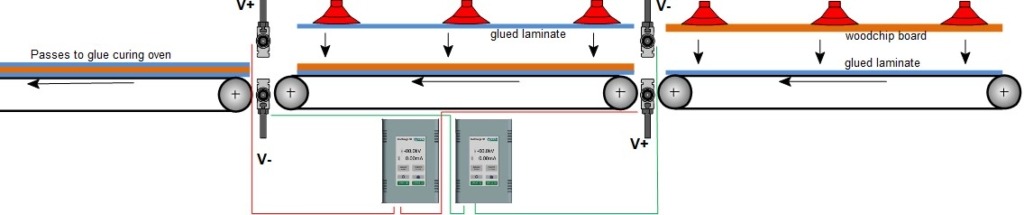

Laminated sheets used for furniture etc, are manufactured by attaching one or two laminates to sheets of man-made board (e.g. MDF). A glue coated laminate sheet is fed on to a conveyor (glue side up) the MDF board is then placed on top. A second glued laminate sheet is added on top, creating a laminate ‘sandwich’. The laminate ‘sandwich’ travels along conveyors to the press where the finished product is formed through heat and pressure. Any air bubbles trapped below the laminate will cause surface blisters on the finished product. There are also possibilities of movement during conveying.

SOLUTION

By installing generator bars opposite each other, the laminate sheets are statically pinned to the board at each stage. Reversing the bar polarity between stages ensures maximum electrostatic forces are applied driving out any trapped are as the stack passes between the bars.

Download- Related Products