Manufacturing of Tufted Carpets

APPLICATION/PROBLEM:

During the manufacturing process of tufted carpets, we encounter contamination issues caused by loose yarns or dust particles. These contaminants pose significant challenges during the subsequent backcoating process. Specifically, the application device becomes dirty due to the presence of these particles, which can lead to inconsistencies and defects in the final product.

EXAMPLE/SOLUTION:

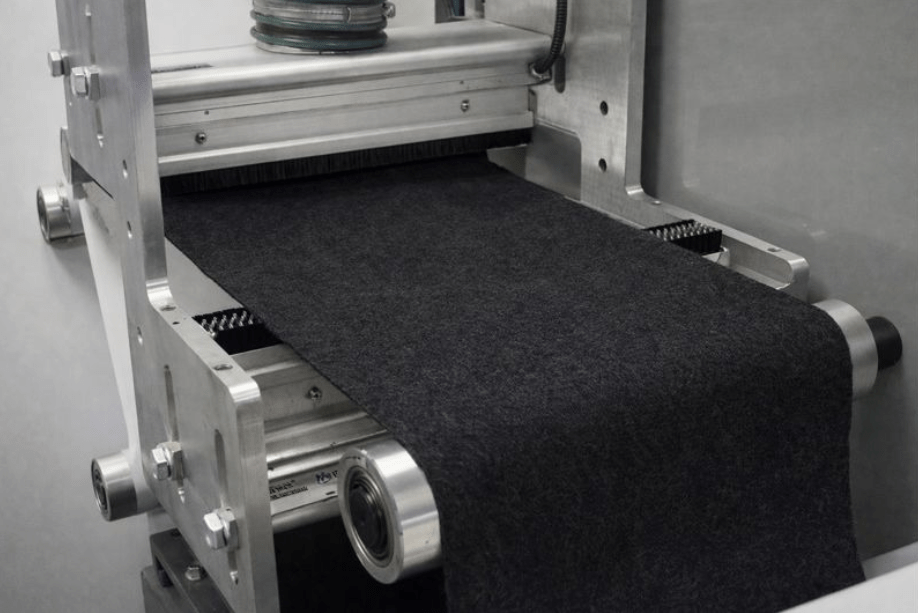

Meech VacClean is the ideal solution to clean fibrous materials such as yarns. A double sided VacClean is installed before the back coating process. This ensures a clean material to coat and minimum defects. Additionally, it enhances efficiency, reduces waste, and extends equipment lifespan, leading to cost savings and smoother operations.

Download

- Related Products