Prototyping and Label Testing

Problem

IML labels are designed to provide high quality graphics on finished products, in a cost effective method. The materials used will affect the ability to use the label in an IML application. Any conductive properties in producing the label, will reduce the pinning strength of the mould tool through the label. It can also allow the charge generated on the label to flow across the surface to earth.

Metallised plastics or conductive inks stop or reduce the pinning effect of the label to the mould tool. This results in label slippage or the label not holding to the mould tool completely.

Surface resistance meters can only provide readings relating to the label face. It cannot provide information about material buried below the face coating.

Solution

The most reliable method of testing the label is to generate a charge on the label while against an earthed plate.

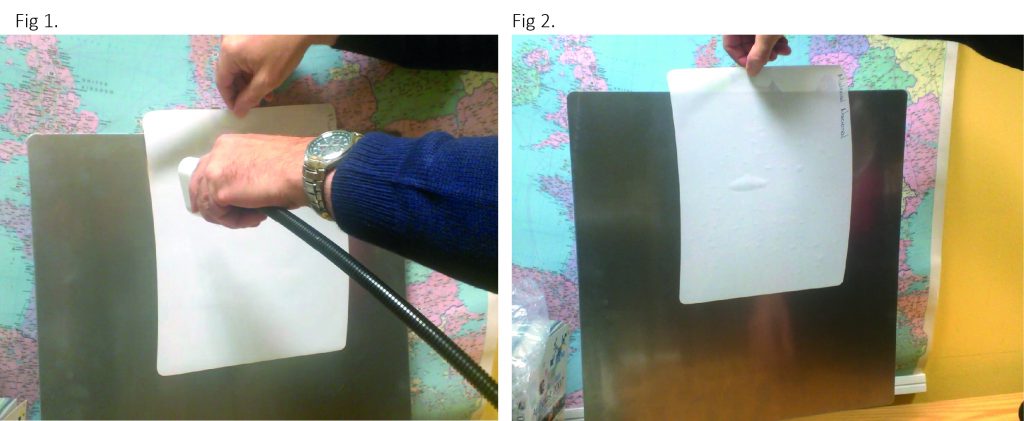

Pictured in Fig.1 a sample label is charged against an aluminium sheet weighing 800g. in Fig.2 the aluminium sheet is suspended using only the applied static charge.

If the label sparks or slips after the charging process has finished, it will not be suitable for IML applications.

This test can be carried out using a Meech B995R-IML-MAN-EXTEND & A994IML generator.

This test equipment is also suitable for:-

- Batch testing stocks of labels to ensure suitability for use in IML applications before putting into stock for later use.

- Manual prototyping of IML products prior to production automation. Small batch sample production for marketing.