Silica Powder Hopper Filling

PROBLEM

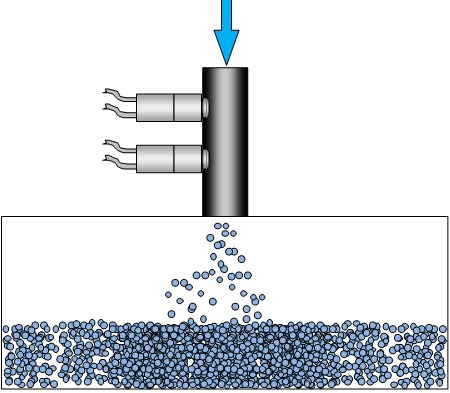

The friction generated by the silica travelling through the transfer pipes generates the static charges on the powder. Silica fills the measuring cup, then the slide valve moves over closing the opening above and opening the valve below, effectively sealing the opening above allowing the measured dose to drop through into the receptacle below.

Static charges cause the silica to stick to the metal slide, reducing the dose transfer.

SOLUTION

Neutralising the silica as it enters the hopper will minimise the effects of static causing the powder to bridge or stick in the filler slide.

Two 261 bulkhead nozzles are used with a power unit to control static charges on the silica.

Download- Related Products