Slitter – CyClean & Static Control

PROBLEM

- Controlling quality prior to supplying to customers is key to repeat orders. Contaminated materials need to be cleaned and slitting dust removed while controlling static charges to a minimum allowing customer processes to be performed at their optimum.

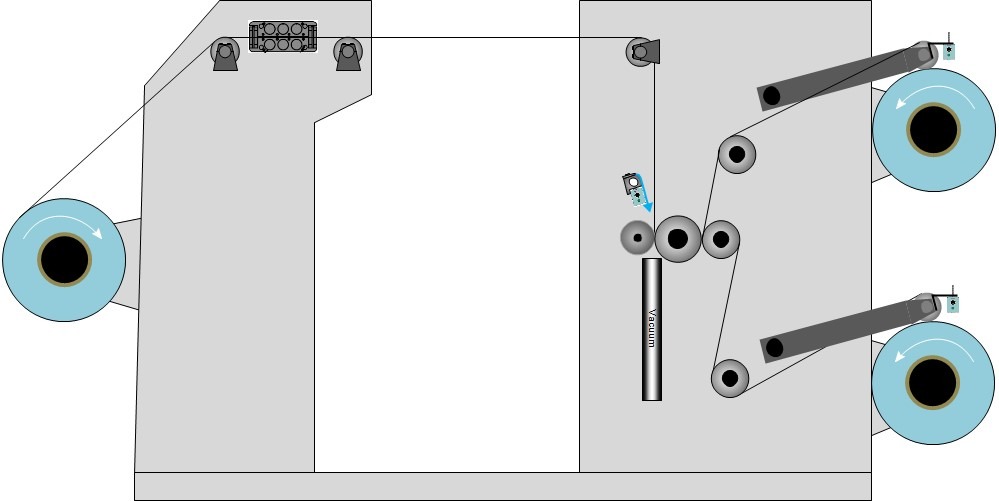

- Areas requiring attention is after unwinding

- Slitting process

- Rewinding

SOLUTION

- Removal of dust and contamination from the material after unwinding is achieved using a non-contact CyClean system provides clean static free material prior to slitting.

- Slitting produces static charges on the edges of the material, introducing ionisation at the point of slitting allows the vacuum extraction to remove the slitting dust

- Installing high-powered high-speed ionisation on the lay-on rollers provides optimum performance on metallised and non-metallised films at high production speeds.

- Related Products