Static Control During Film Rewinding

Problem

Winding up film on extruded or blown film lines produces high levels of static electricity, often in excess of 200 kV. This can lead to a number of major problems:

- Operators can receive painful and unpleasant shocks

- High levels of static in the reel can cause production problems for the customer

- Dust can be attracted from up to 1 metre away, leading to contamination of the film.

Solution

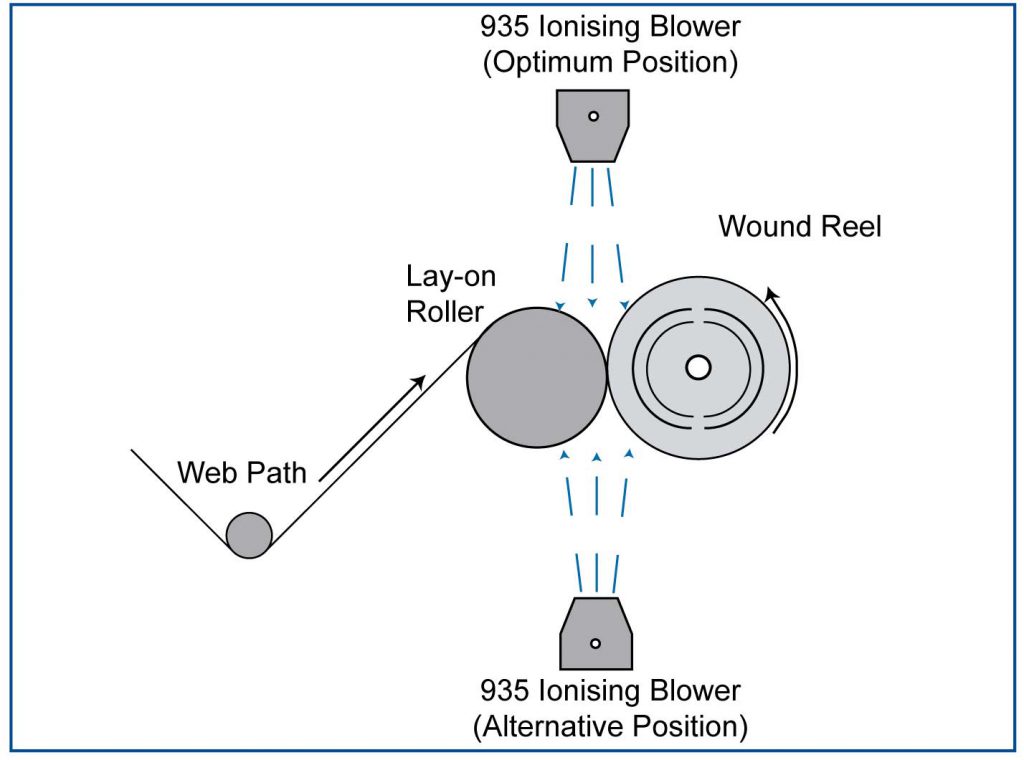

The correct selection of equipment will be driven by the design of machine, space constraints etc. The model 935 fan driven ionised air blower delivers a high volume of concentrated ionised air to the wind on. The gentle flow of ionised air spreads from the blower head to give wide coverage as well as long range neutralisation. Long range ionisation ensures neutralisation of the entire film roll. Fan filters are available to ensure that only clean air is projected at the film.

Download