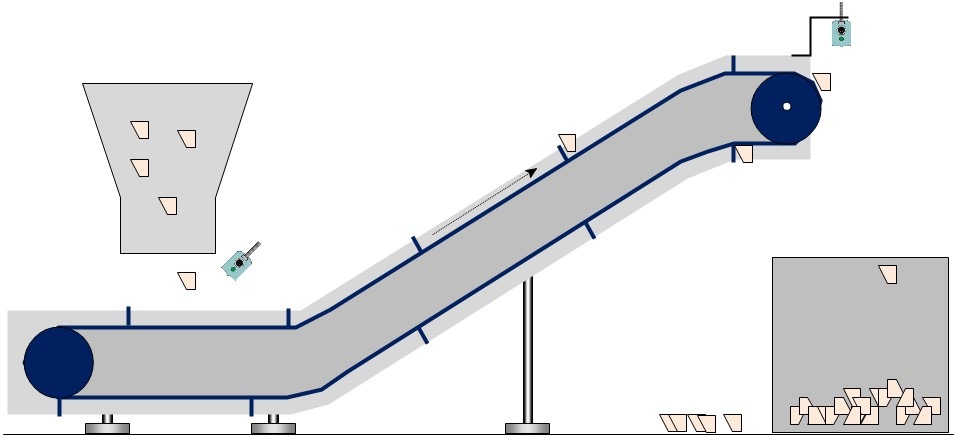

Static control on step conveyor

PROBLEM

Static charges on granulated recycled plastics cause issues with false readings with metal detectors, dust & plastics sticking to conveyor, then dropping onto the floor. This creates additional work and waste product.

Static discharges are detected by metal detectors and seen as metal in the product. This results in material being diverted into waste bins.

Controlling the static charges are key to keeping the operation efficient.

SOLUTION

Neutralising the product as it drops onto the stap conveyor, allows for all surfaces of plastic and dust to be neutralised aiding separation from the conveyor.

A second bar at the end of the conveyor removes charges that may have rebuilt and helps suppress airborne dust issues.

Preventing static discharges, removes false signals from activating metal detectors.

Download