Static Pinning Gusset Into Flat Bag

Problem

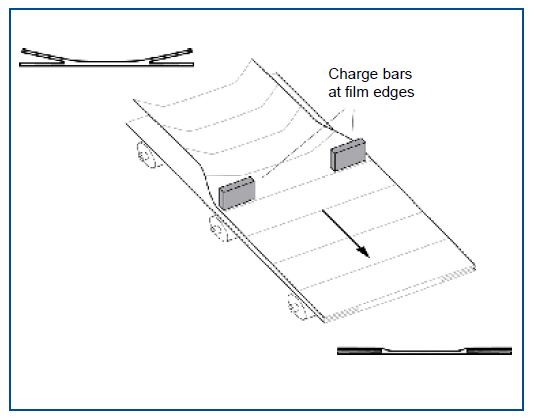

Traditional carrier bags are manufactured from a continuous web of material. In some cases the material is folded to create a gusset along each side. With the gussets created, the web passes through a sealing head to form individual bags.

As the web travels through the machine prior to the sealing head the folded gusset can slip out of shape. This is generally caused by air entering the folded gusset and opening it up. This results in bags being sealed with an incorrect gusset, causing waste and loss of production.

Solution

The gusset can be pinned together to stop it slipping out of position prior to sealing by installing a Meech 993R generator bar opposite a metal roller (ground). This results in the bags being sealed correctly, reducing waste and downtime. The 993R bars are connected to a 992v3 30kV generator to provide powerful pinning.

Download- Related Products