Static Pinning On Side Weld Bag Handles

Problem

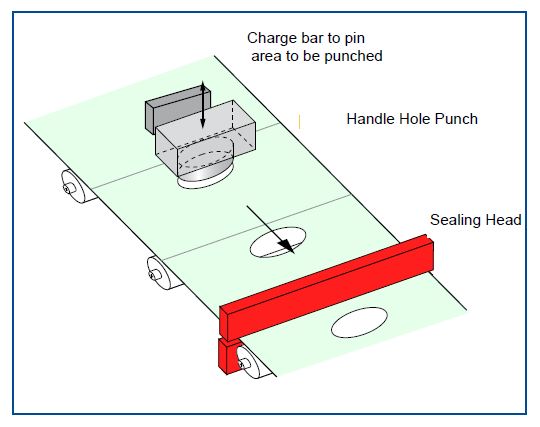

To provide a handle for bags made in this way, an in-line punch is used to cut a handle shape from the web prior to the cut/seal head. During the manufacturing process the web is ‘pulsed’ forward according to its required length. Whilst momentarily stationary, a punch cuts the shape for the handle. When the web moves forward again air can enter the plastic tube, causing a jam at the sealing head.

Solution

A Meech 993R static generator bar is placed in-line and prior to the punch. It is synchronised with the punch to pulse ‘on’ to pin the web closed. This prevents air from entering when the web moves forward. The 993R bar is connected to a 992v3 30kV generator to provide powerful pinning.

Download- Related Products