Tamper Seal Issues Due To Powder Inclusion In Seal

Problem

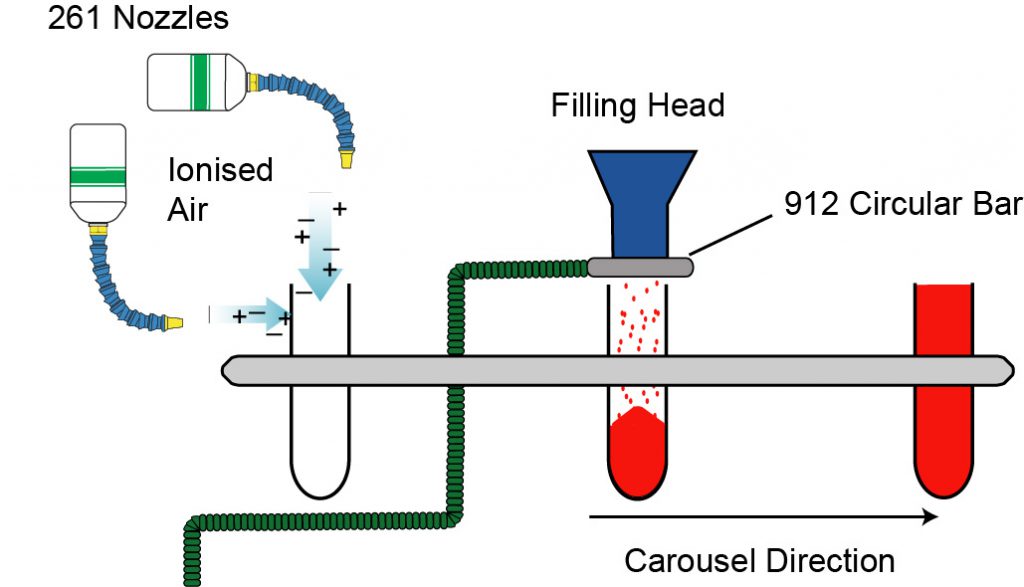

During the packaging of powders in small plastic containers, the containers are typically delivered on a carousel indexing round from a feed system, through a filling station to a delivery system. Problems can occur due to product misbehaviour during the filling operation:

- Powder adheres to the outside and coats the inside walls of the container.

- Powder adheres to the filling head.

The build up of powder eventually leads to mis-filling whilst contamination of the outside of the container can lead to rejection by the customer.

Solution

Two 261 Nozzles are positioned at the index position immediately prior to the filling station. One nozzle is directed at the outside of the container, the other at the inside. A model 912 Circular bar is positioned around the filling head level with the end of the dispensing tube.

Powder attraction to the container walls and accumulation on the filling head is eliminated.

Download