Vegetable Drying using Non-Ionising JetStream System

Problem

Battoned carrots are sliced, washed and transported in water. Carrots then travel on a vibratory conveyor and pass under a Jet Stream Manifold to be dried. The carrots are then packaged using a vertical form fill and seal machine. The following problems can occur:

- Wet product has a reduced shelf life when packed.

- Wet product becomes discoloured and unattractive to the consumer.

- Packaged product weights can be incorrect due to water content.

Solution

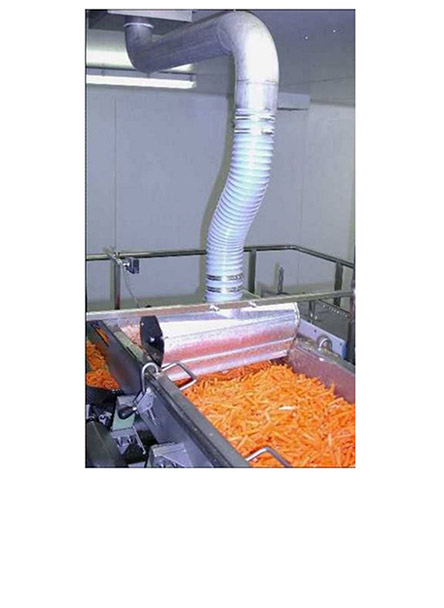

Installation of a Meech Jet Stream, Air Knife Drying System:

The Jet Stream High Pressure Fan Unit is installed in the roof space above the production area. The air is ducted to the Manifold in both rigid and flexible ducting. The small length of flexible ducting allows the Manifold to be raised and/or lowered dependant on the depth of carrot on the vibratory conveyor.

Download- Related Products