수소 연료 전지

Contamination removal in hydrogen fuel cell production

HFC technology will be an essential part of zero carbon emissions solutions. It is very clean compared to internal combustion engines with the output by-product being H2O. HFCs are likely to be paired with battery technology but are forecast to be supplied in smaller volumes into passenger automotive sector and more significantly into heavy goods vehicles, buses, shipping, material handling and even aircrafts and drones.

While it has been slower to evolve and scale-up than battery technology, it is now being actively industrialised with a focus on improved automation of key process stages.

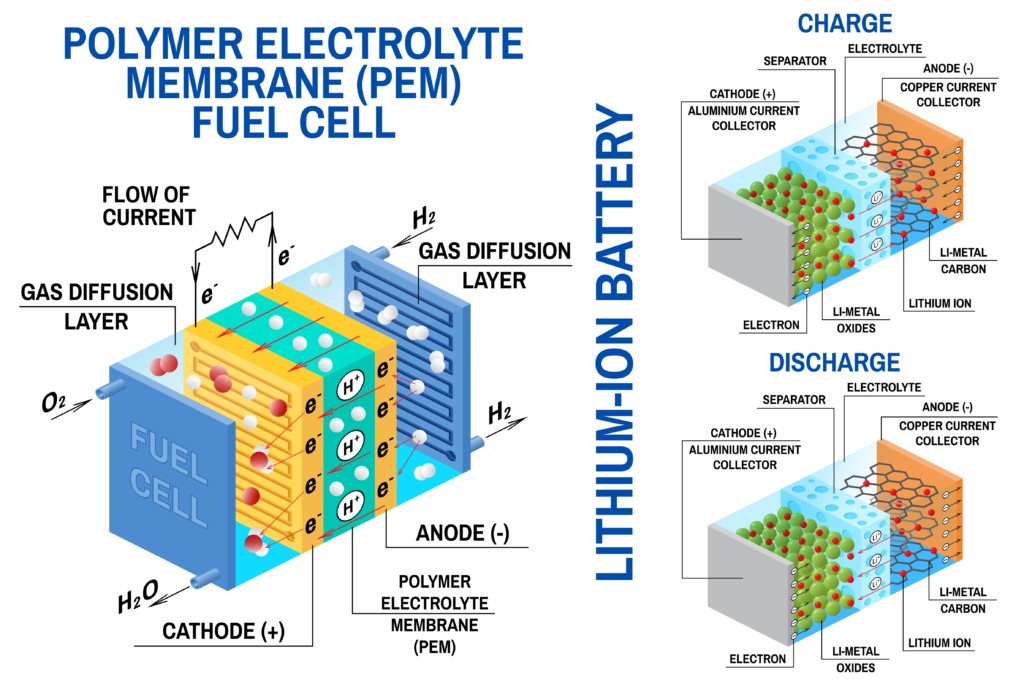

Meech has been engaging with scale-up partners in industrialising the production processes of PEM fuel cells (proton exchange membrane) which is most commonly being adopted in the automotive sector. It is essential to avoid embedded contamination and high static charge in the cell components and Meech will work with our partners to determine the optimise solution based on available space on machine, type and characteristics of contamination and process environment. By avoiding these risks, production speeds can be optimised, yields can be maximised, and latent defects can be avoided.

당사의 제로 결함 전진 접근 방식

We have identified a number of processes within hydrogen fuel cell manufacturing that are prone to contamination on the line. By applying the right solutions at these points, you make sure there are no weak links to your production chain. We explore these below and demonstrate our solutions…

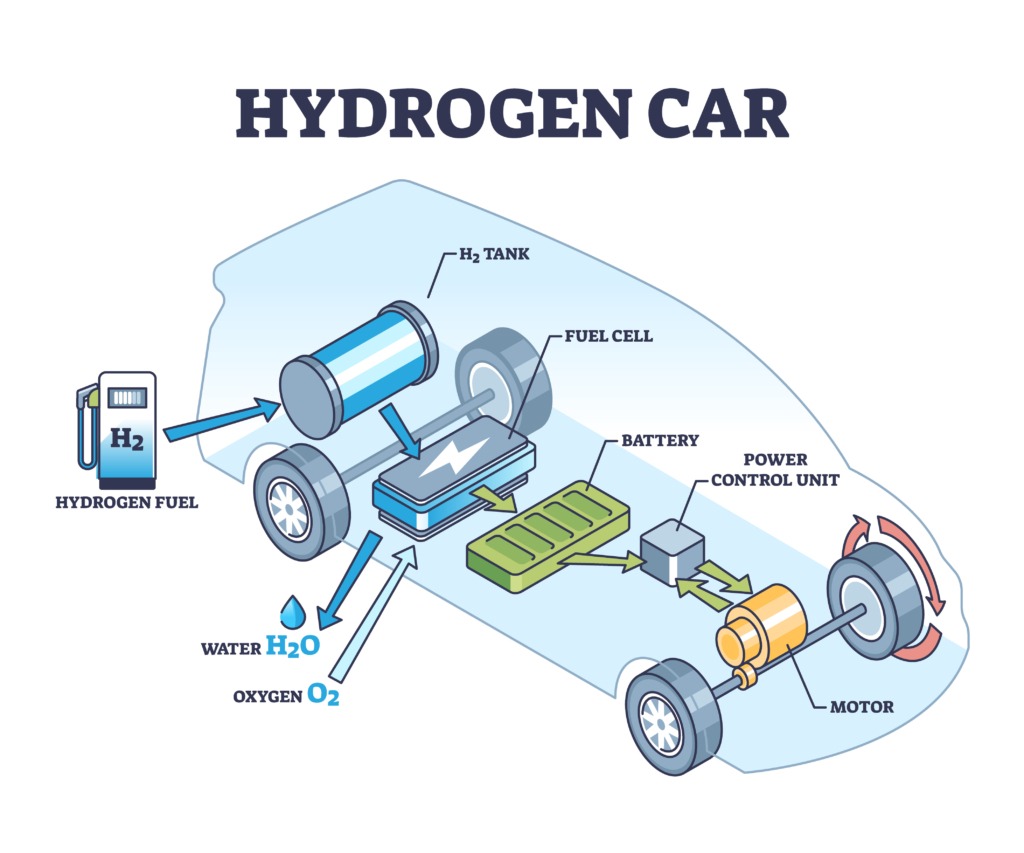

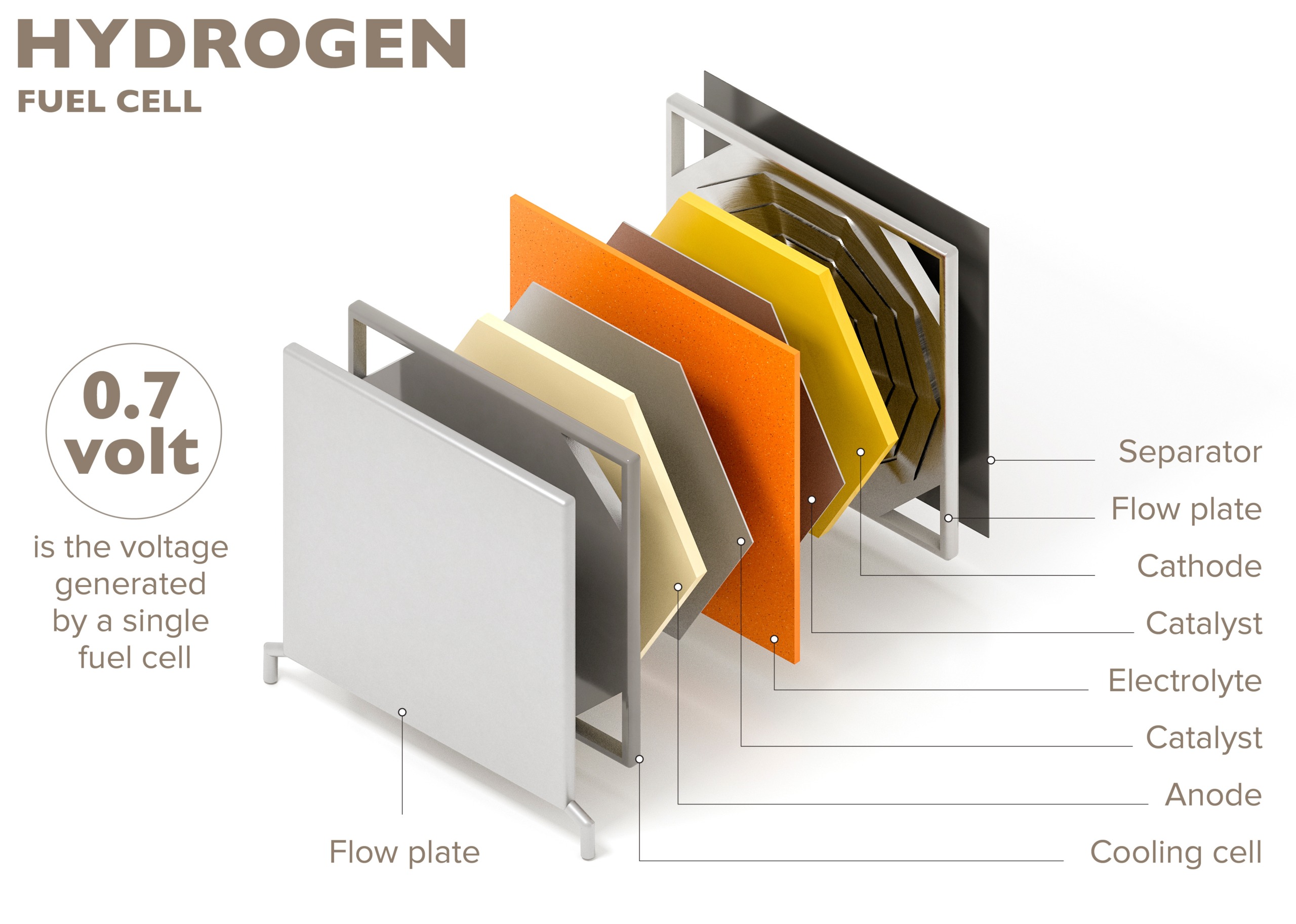

What is a Hydrogen fuel cell?

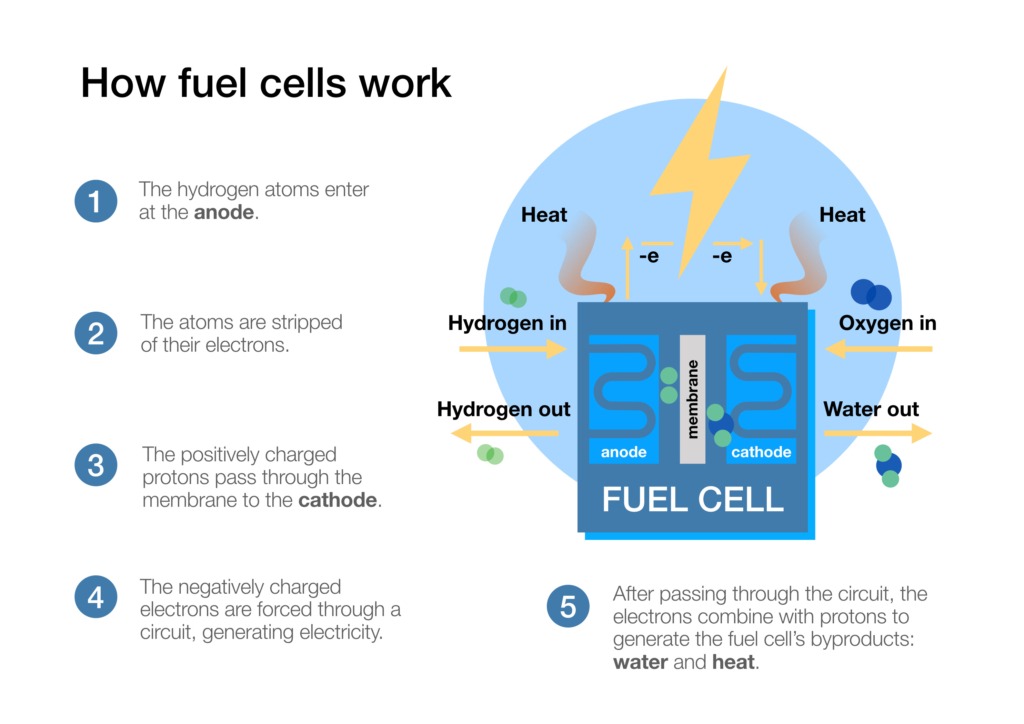

Fuel cells are devices that generate electricity through “electrochemical redox reactions” (not combustion – they don’t burn anything).

In short, they convert chemical energy of fuels (hydrogen or methane) directly into electrical energy (by combining them with oxygen). As the chemical conversion does not need thermal and mechanical energy first fuel cells are (by comparison) 매우 효율적이다.. Besides minimizing energy losses, fuel cells are also far less polluting than classic combustion engines with carbon emissions being much lower and non-toxic.

If “green” hydrogen (hydrogen created using renewable energy sources) is fuelling the cell, they only emit water vapour and warm air! Delivering overall a very clean power solution.

보완 기술

Fuel cells and batteries are two viable solutions to create electric powertrains and thus address the clean energy challenge. Both technologies will also have their place as a 하이브리드 솔루션 (combined). Depending on the application, either can be the best answer.. (we will also see them in combination)

주요 차이점

The single most essential difference between fuel cells and batteries is simple: a battery stores energy which it then uses, whereas a fuel cell generates energy by converting available fuel. As long as you have access to the fuel, you have access to electricity – anytime, anywhere. Interestingly, a fuel cell can also have a battery component to store the energy it is generating.

Meech has been engaging with scale-up partners in industrialising the production processes of battery cells and PEM fuel cells (proton exchange membrane) which is most commonly being adopted in the automotive sector. It is essential to avoid embedded contamination and high static charge in the cell components and Meech will work with our partners to determine the optimise solution based on available space on machine, type and characteristics of contamination and process environment. By avoiding these risks, production speeds can be optimised, yields can be maximised, and latent defects can be avoided.

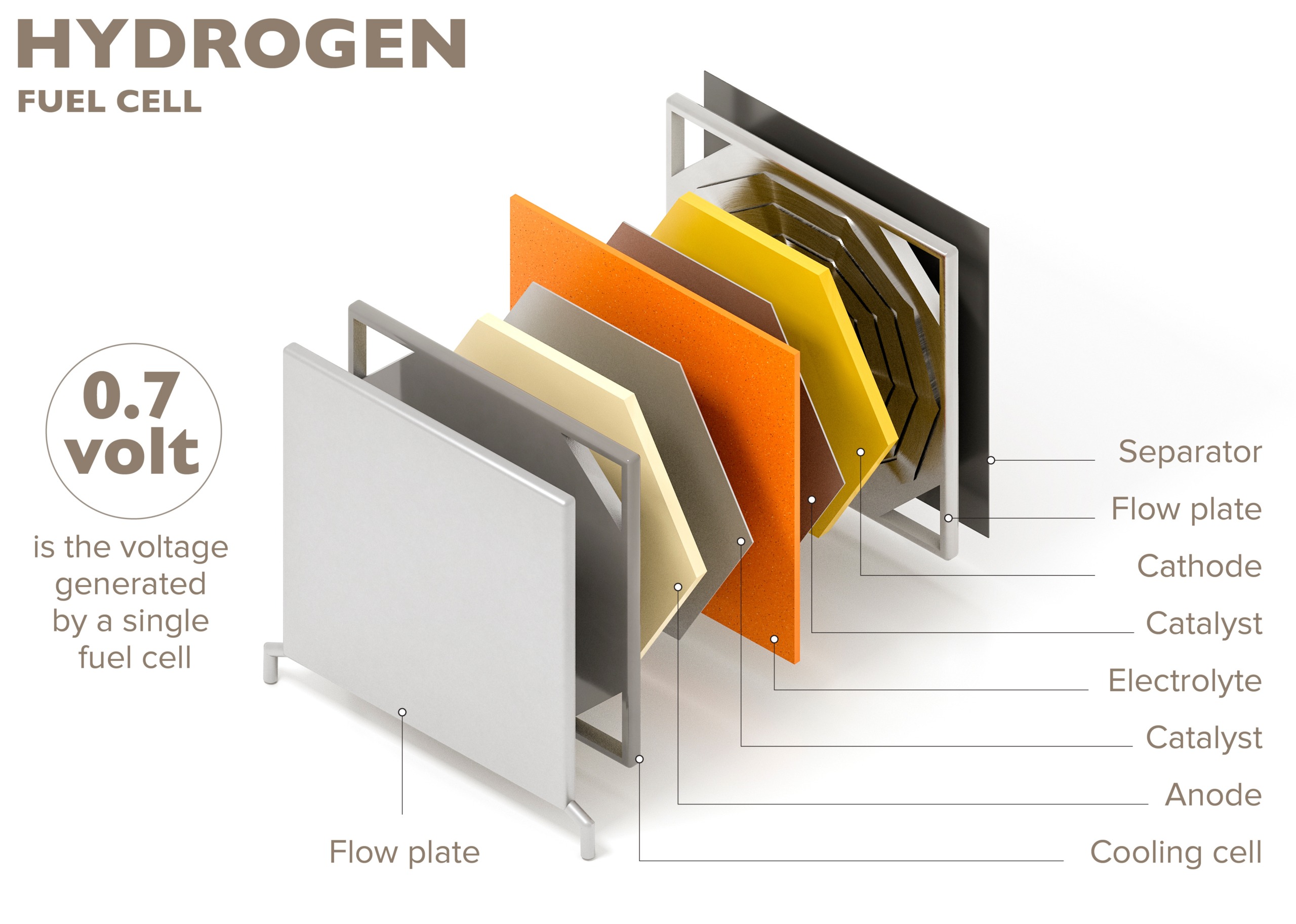

primary components of the hydrogen fuel cell

Bi-Polar Plates

Bi-polar plates are designed to channel hydrogen, conduct electrons and dissipate heat from the cell:

Micro Porous Carbon Paper or Non-Woven Material

Micro porous carbon paper or non-woven material is designed to ensure there is a consistent flow and transfer of active media across the membrane:

Catalyst Coated Membrane (CCM)

A critical part of PEM fuel cell membrane is the CCM (catalyst coated membrane). This is a polymer membrane coated with anode and cathode on either side. When automating key production stages of this component in a roll-to-roll converting format, it is critical to eliminate static charges and avoid embedded contamination so the final CCM component is fully optimised and not rejected or carried forwards with a latent defects.

Primary applications: Catalyst coated membrane production

Dry Coating Stage on to Carrier Film

In the first stage, the Anode and Cathode coating material is separately coated onto a ‘carrier’ PTFE or PE carrier film (before being dried and then transferred on to each side of a single moisture sensitive polymer membrane).

Anode and Cathode carrier rolls are produced separately.

Referring to the image above, prior to coating, the carrier film must be free of contamination and neutralised of static charge (created upstream and during unwind process) – ensuring coating accuracy and stability is maintained and materials flow through converting process without difficulties.

It may also be required to clean the coating roller to help maintain a consistent calliper of coating.

As the coating layer is dried, heat related crystals can be generated from the carrier film (on underside) and this requires a specialist contact type removal process to prevent membrane damage or cross-contamination to other components.

The anode or cathode roll is then transferred to the next production stage (with zero faults carried forwards).

A combination of non-contact and contact type web cleaners are recommended – all Meech web cleaners include static ionisation bars to neutralise materials.

Several essential cleaning and static control processes are required to avoid embedded contamination and high static charge build up as shown in the above diagram.

Other critical processes exist which are being investigated as the industry increasingly adopts automation techniques.

It is also possible that live performance monitoring and date logging is needed for more critical static control solutions.

If you are designing a pilot or scaled up battery production line or have existing contamination or static charge related challenges, please get in touch with one of our Meech industry experts.

(See bottom of page for frequently required solutions).

Coating Transfer Stage onto Polymer Membrane

In the next stage, separate rolls of cathode coated and anode coated carrier films are unwound with the dry anode and cathode catalyst coatings facing towards polymer membrane.

Through a combination of compression and heat the “decal” anode and cathode coating is transferred onto each side of the polymer membrane.

The catalyst coated membrane (CCM) is then wound into a roll for next process stage.

Several essential cleaning and static control processes are required to avoid embedded contamination and high static charge build up as shown in the above diagram.

Other critical processes exist which are being investigated as the industry increasingly adopts automation techniques.

It is also possible that live performance monitoring and date logging is needed for more critical static control solutions.

If you are designing a pilot or scaled up battery production line or have existing contamination or static charge related challenges, please get in touch with one of our Meech industry experts.

(See bottom of page for frequently required solutions).

* 모든 그림은 설명 목적으로만 사용됩니다. 귀하의 공정에 가장 적합한 정전기 제어 및 웹 청소 솔루션의 위치는 귀하의 응용 분야의 특정 요소에 따라 달라집니다.

웹 클리닝 솔루션

Meech는 포괄적인 4가지 시스템을 갖춘 선도적인 웹 클리닝 제조업체입니다. 각 시스템은 서로 다른 세척 원리를 기반으로 하며, 이를 통해 당사는 고객의 용도에 가장 적합한 시스템을 제공할 수 있습니다. 모든 Meech 시스템에는 최신 충격 방지 장치가 포함되어 있습니다. AC 정적 제어 바 이는 포괄적인 오염 제거에 중요한 표준입니다. Meech는 포장, 인쇄 및 변환을 포함한 다양한 산업 분야에서 200개 이상의 성공적인 웹 클리닝 설치를 보유하고 있습니다.

싸이클린™

비접촉 웹클리너

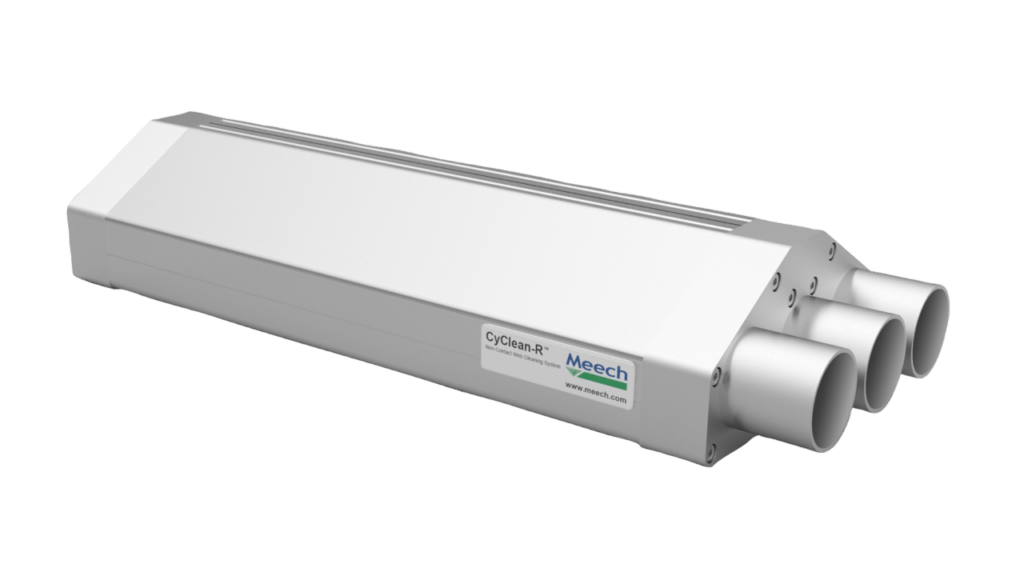

싸이클린-R™

비접촉 웹클리너

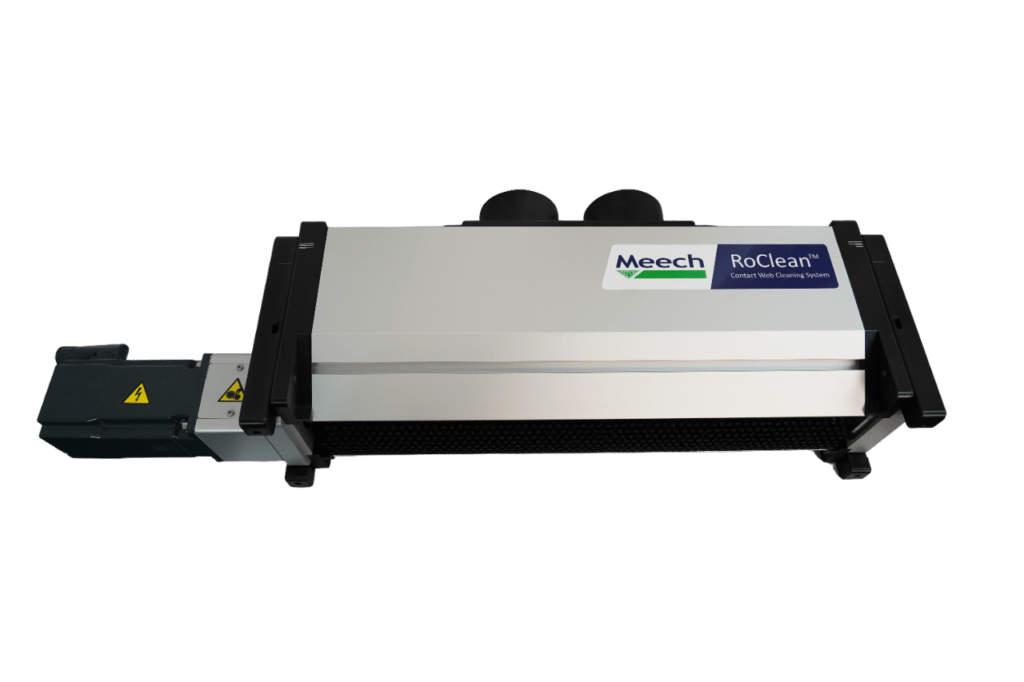

로클린™

Contact Web Cleaner

공기 조화 기

Meech CyClean™은 소형, 고성능, 비접촉 웹 클리너에 대한 수요에 부응하여 설계되었습니다.

CyClean은 첨단 전산유체역학을 적용하여 1미크론 미만의 오염물질을 제거하고 추출합니다.

CyClean-R은 저압 웹 클리닝을 위한 특수 솔루션을 제공합니다.

CyClean-R은 웹 장력이 가장 높은 롤러에 위치하도록 설계되어 장력이 낮은 문제를 우회하면서도 우수한 표면 청소 기능을 제공합니다.

RoClean is the latest contact web cleaner, delivering excellent surface cleaning results for the battery film manufacturing industry.

RoClean effectively cleans the web surface through the use of both static control and an efficient bristle roller brush.

Meech web cleaners are supplied with Meech Air Handling Units (AHUs) to ensure air balance is maintained to perfectly control accuracy of air pressure and vacuum. These are compact, industrial specification units and can also be performance monitored via PLC control.

For the battery environment a new AHU option has been developed to enhance toxic contamination waste entrapment and safe filter removal by the operator.

정적 제어 솔루션

Meech는 1960년대부터 정적 제어 제품을 제조 및 공급하는 시장 선두업체입니다. 정전기 방지 및 ESD 보호 및 측정, 정전기 발생, 정전기 제어 및 제거 기능을 제공하는 광범위한 정전기 제품을 제공합니다.

하이페리온™

924IPS 이온화 바

하이페리온™

피드백 센서

983v2 정적 위치 탐지기

하이페리온™

스마트컨트롤 터치

24V DC로 구동되는 Hyperion 924IPS는 시중에서 가장 컴팩트한 펄스 DC 바입니다.

924IPS는 Meech의 ICM(이온 전류 모니터링) 기술을 갖추고 있어 바를 청소해야 할 때 로컬 및 원격 경고를 통해 성능이 유지되도록 보장합니다.

Our closed-loop feedback system takes advantage of the adjustable balance of pulsed DC ionising systems.

The system comprises a Hyperion SmartControl and up to 5 Hyperion ionising products for closed-loop feedback. Once connected to the SmartControl sensor, measures the voltage on the web downstream of the ionising bar.

This measurement can be fed back to the ionising product which automatically adjusts the balance of the output to achieve a completely neutral web. This is a continuous process that constantly measures and adjusts to achieve the very best static control at all times.

The Model 983v2 Static Locator provides a clear indication of electrostatic charges on materials. It is intended for general industrial use and has a wide measuring range of +/-200kV, measured at 150mm distance.

The 983v2 can operate in “Continuous” or “Peak Hold” mode to record changes in the level of charge or the highest charge detected respectively. It is suitable for providing a good indication of the level of static charge for use by production, maintenance, inspection and quality engineers. The 983v2 can be used on any material where static charge may be an issue.

SmartControl Touch는 현대 자동화 산업의 요구 사항과 Industry 4.0의 성장을 충족하여 생산성과 출력 품질을 극대화하도록 설계된 Meech의 최신 혁신 기술입니다.

SmartControl Touch를 사용하면 사용자는 통합 터치스크린을 통해 또는 원격으로 연결된 여러 Hyperion 이온화 바와 센서의 성능을 모니터링, 제어 및 조정할 수 있습니다.

Could we help improve your hydrogen fuel cell manufacturing process?