Meech International will be returning to Labelexpo Americas (13th – 15th September, Rosemont, Illinois) to cement its position as the world’s leading provider of web cleaning solutions for the labelling industry. Visitors to booth 551 will be able to view first-hand the company’s unique range of contact and non-contact web cleaning technologies, including the CyClean and the TakClean systems, as well as the company’s popular Hyperion anti-static bars.

“The need to minimise wastage and achieve higher levels of productivity is a key priority for label printers and converters, who often struggle to determine the best solution for removing contamination from their web process,” says Matt Fyffe, VP/General Manager at Meech USA. “For this reason, we look forward to exhibiting our web cleaning technologies to the label industry at Labelexpo Americas. Contact and non-contact cleaning methods come with their own set of advantages and it is our job to help the customer evaluate which is the better option for their business.”

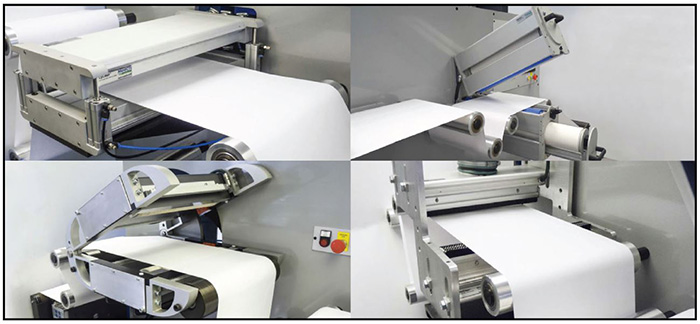

Narrow web presses used by label converters traditionally adopt tacky roller contact systems like Meech’s TakClean to efficiently remove contamination. These systems use elastomer rollers to remove dry, unbonded contamination from a moving web, which is then transferred onto adhesive roles where it is trapped. The design of the system also allows operators to see the contamination being collected on the adhesive roll.

For substrates carrying higher contamination levels, non-contact systems are used. Non-contact web cleaning has the advantage that the contamination level does not affect the system performance and no consumables are required, which in turn reduces ongoing costs. Meech’s CyClean system is capable of removing 0.5 micron contaminants and will deliver higher levels of cleanliness for label printing applications.

“What sets the CyClean apart from other web cleaning systems is the inclusion of an Air Handling Unit, or ‘AHU’,” explains Matt. “The latest model, the AHUv3-Compact has an even smaller footprint than previous models and includes a new touch screen display. The system also has improved blowing and vacuum airflows and filtration for the system through an F8 grade washable bag filter, which can be upgraded to a HEPA filter for installations in very clean environments.”

He concludes: “Web cleaning systems need to achieve two main actions: the boundary layer of air on the web must be broken, allowing contamination trapped under and within it to be removed, and the static charge on the web must be eliminated so that contamination can be isolated. Meech’s systems deliver on both fronts and we’ll happily demonstrate to booth visitors that they can expect the highest quality finish from all our products.”