SmartControl™ Touch

Product Code: ASMARTCON-TOUCH-LAN

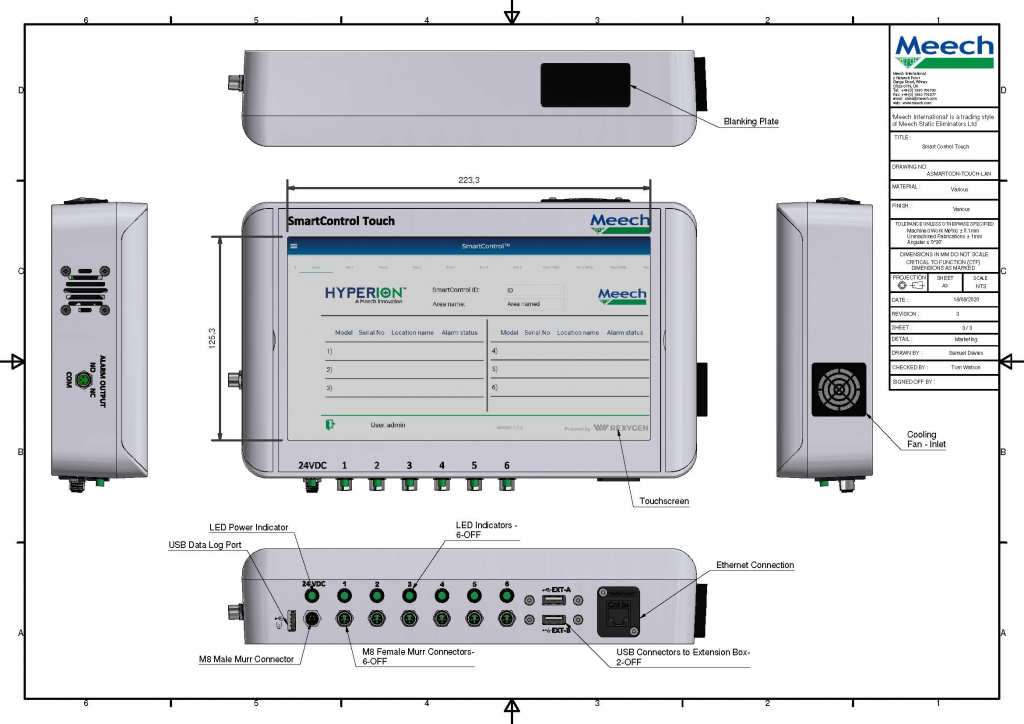

The Hyperion SmartControl™ Touch, like our BarMaster Programmer, controls our Hyperion™ ionising bars and sensors. SmartControl™ allows users to monitor, control and adjust the performance of multiple connected Hyperion™ products through an integrated touchscreen or remotely via a mobile phone, tablet, touchscreen or monitor. Thanks to our ion current monitoring technology, users can easily monitor ionisation performance. As a result, users can make adjustments in real-time, making SmartControl™ ideal for process operators who prefer to use their own local display unit.

Users can link the SmartControl™ with up to six devices. Furthermore, by adding an extension unit, they can connect twelve more devices. With a maximum of two extension units per SmartControl™ Touch, it can control up to 30 devices simultaneously.

SmartControl™ also features a contact-free alarm output that signals status and cleaning alerts, helping operators maintain a smooth and efficient production process.

Optional features include PLC Industrial Network Integration and feedback sensors.

We design SmartControl™ to meet the demands of modern, automated industries and the evolution of Industry 4.0. With this, operators gain full control over static electricity, ensuring greater performance.

DownloadFeatures & Benefits

Monitor and control via touchscreen or remotely on any device.

Connect up to six devices per SmartControl™.

For fast and easy installation into current operations with immediate effect.

Contact free alarm output to signal alarm status.

SmartControl™ logs data for on-screen graphs or CSV export.

LAN or industrial network (PLC-compatible). Extension unit supports up to 30 devices.

Technical Characteristics

ASA + PC & FR.

USB and RJ45, plus optional industrial network connectivity.

280mm x 170mm x 59mm (W x H x D).

30 devices in combination with extension units.

1.2kg.

96W required.

24V DC, M8, 4-pole Murr.

Yes.

4 x case mounts.

LAN or industrial network (PLC-compatible). Extension unit supports up to 30 devices.