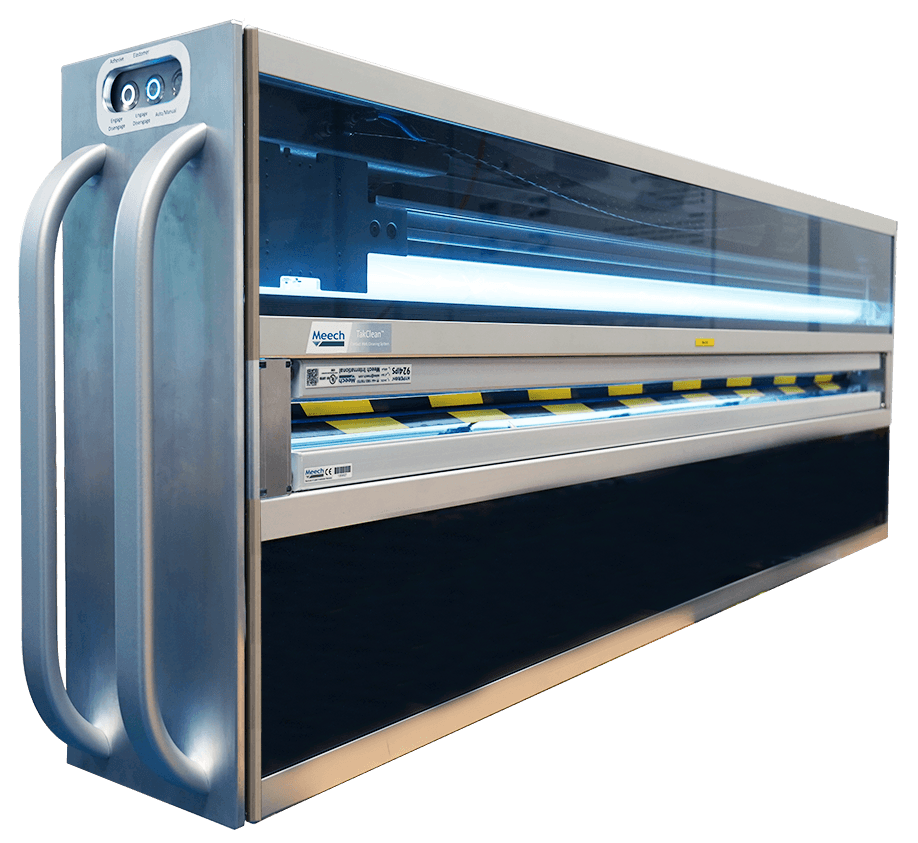

TakClean™ Ultra Contact Web Cleaning System

Product Code: TakClean Ultra

The Meech TakClean Ultra is the latest contact web cleaner from Meech, a re-design of the hugely successful Meech TakClean system. Delivering excellent surface cleaning results and manufactured specifically for medium and wide webs between 650mm and 1,450mm. Built to the highest quality standard, the TakClean Ultra offers something new to tacky roller cleaning.

TakClean Ultra’s pneumatics’s are used to hold the TransTak Elastomer cleaning rollers in place, offering an even and consistent level of pressure across the full width of the web; with dry unbound contamination then lifted from the web surface. Pneumatics are also used to hold the adhesive roller against the TransTak Elastomer roller. Contamination is transferred from the surface of the TransTak roller to the adhesive roller, where it is trapped. Any static present on the web is neutralised on exit from the TakClean Ultra by 2 x Hyperion 924IPS bars. This minimises the risk of recontaminating the web.

DownloadFeatures & Benefits

Every component is self contained within the TakClean Ultra, so there is no additional space requirements. This means the TakClean Ultra can fit into areas that require a small footprint.

The latest DC static control technology neutralises the web surface as it exits the TakClean Ultra. This reduces the risk of recontaminating the web. Automatic Ionisation means the static control will only be switched on when the elastomer roller is engaged. This will increase the life of the static control.

Independent rollers mean that you can disengage the adhesive roller whilst the Elastomer roller is still engaged, allowing for efficient and uninterrupted cleaning. Changing the adhesive roller can be done easily and quickly, reducing downtime and making webbing up easy and contact free.

Provides flexibility and allows different material to run on the same production line.

Allows the TakClean Ultra to be controlled either manually, via the direct TakClean Ultra controls, or automatically via independent external controls. Both the elastomer and adhesive rolls provide remote signals.

Smart design allows the 924IPS bars to be easily mounted on either side of the unit. Meaning the direction of the web can be reversed at anytime, providing maximum user flexibility.

To suit a vast range of applications.

Making webbing up easy.

Provides protection against accidents, whilst also protecting the adhesive rolls from external contamination.

Allows for quick and easy set up and maintenance.

LED lights built into the TakClean Ultra show any contamination left on the web. Allowing the user to identify issues immediately.

The design of the TakClean Ultra means there is very little wear on parts. This will extend the life of the System.

Allows easy set up of the pneumatics.

Technical Characteristics

250 m/min, 820 ft/min

110/240V at 50/60Hz connection

4-7 bar (58-100psi)

2x 924IPS Pulsed DC Ionising Bars