Aerosol packing line

PROBLEM

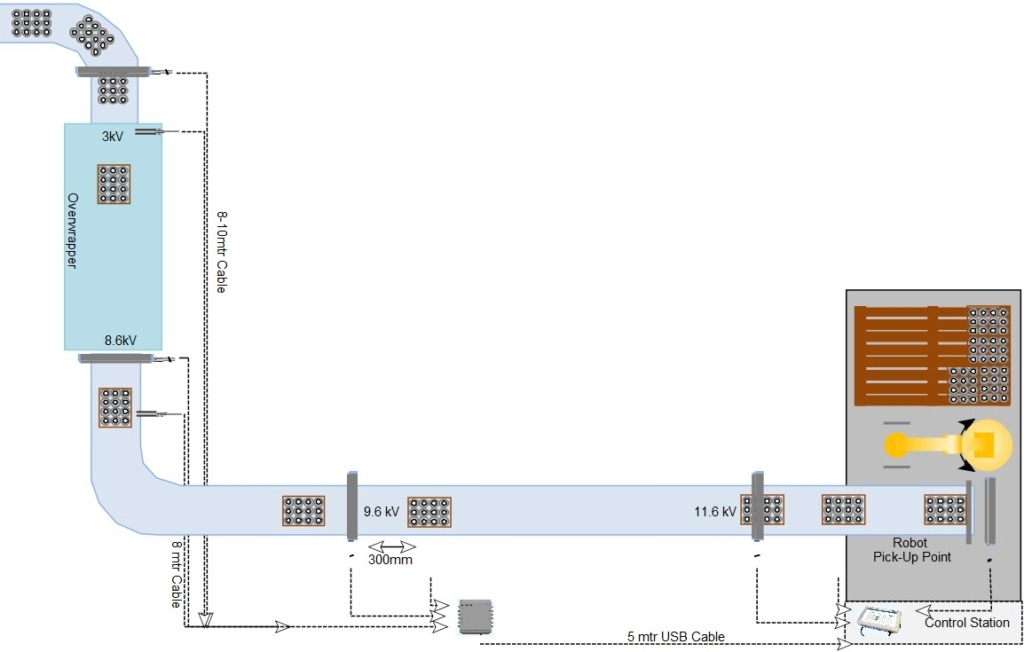

During the overwrapping and shrinking process, static charges are generated on the shrink sleeve. In the event where an aerosol canister leaking gas, the risk of a static discharge creates a high risk of fire.

SOLUTION

Controlling and monitoring the static charges during the packing process, ensures the risk of fire is minimised. Smart Control provides the monitoring of the ionising systems connected, while feedback sensors monitor residual charges.

Linking sensors to bars via the SmartControl Automates the adjusting the ioniser’s performance to compensate for charges detected. This constant monitoring is recorded in real-time, providing a historical log, and alarm outputs provide warnings in the event of a problem.

The alarm output can be linked to the machine’s emergency stop, central monitoring station, strobe, or audible alarm. This provides a safe working environment for staff and the production process.

Download

- Related Products