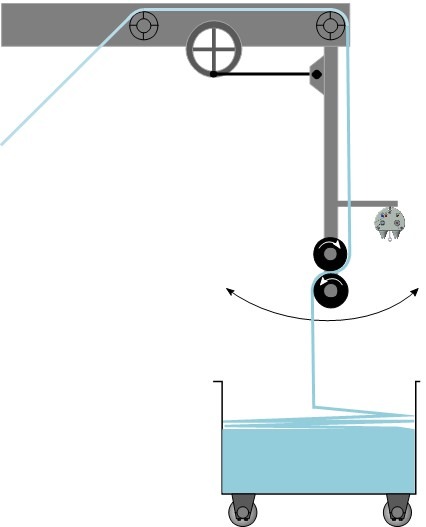

Plater delivery machine

PROBLEM

Textiles are delivered directly into a plater trolley via a swing arm. The following problems can arise:

- Static causes the product to cling or attract onto the frame sides

- Contamination of product due to dust attraction

- Operator shocks

SOLUTION

Mounting a 971IPS on a bracket, allowing the bar to stand 200mm off the product path, behind the nip rollers on the swing arm ensures that the product is fed onto the frame free of static. The pendulum action sends waves of ions down on to the product allowing filling to be controlled with the same method.

The Model 971IPS bars also ensure the product is contaminant-free and the risk of shocks to the operators is removed.

Download

- Related Products