ESD Damage Or Weakening Of RFID Tags During Die Cutting

Problem

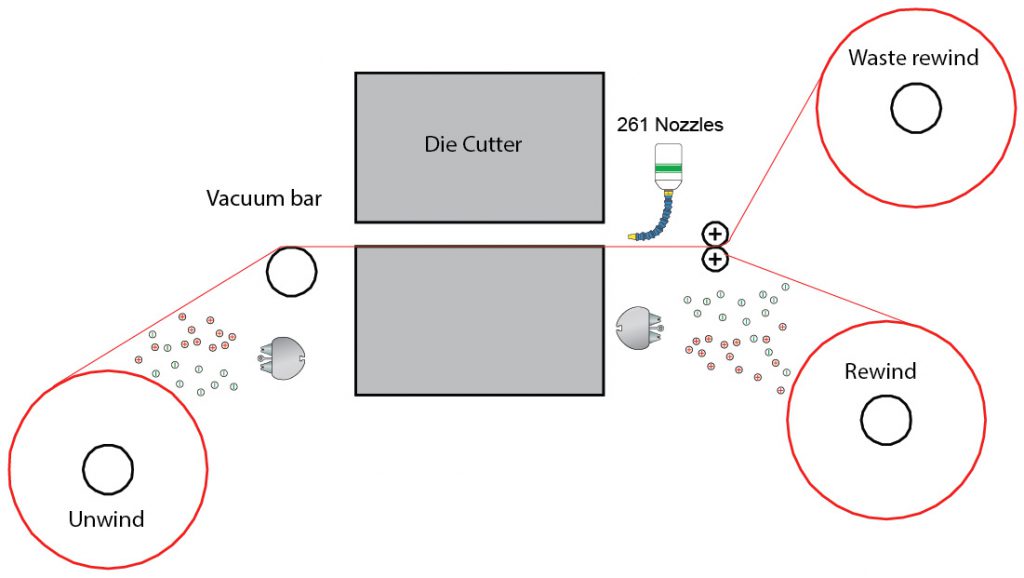

RFID tags are received on a reel, unwound and guillotined prior to application on to the product. The tags are easily spoilt by static discharges and require good static control during processing

Static charges generated through the un-wind can exceed the tolerance levels on RFID or security tags and can cause the following associated problems:

- Static charges blowing the RFID chip and rendering it useless

- Operators receiving unpleasant shocks

- Attraction of dust and other airborne contaminants.

Solution

A model 971 and 977CM aimed at the nip of the unwind and rewind rolls will bathe the reel in ionised air, neutralising any static charge on the reels will prevent electrostatic discharges resulting in EMP and damage to the chip. Further neutralisation will be required during the seperation of the guillotine. This needs to be implemented by using Meech 261 flexi nozzles to blow ionised air into the die to neutralise it.

Download- Related Products