Fire Prevention During Coating Film using Solvent-Based Coatings

Problem

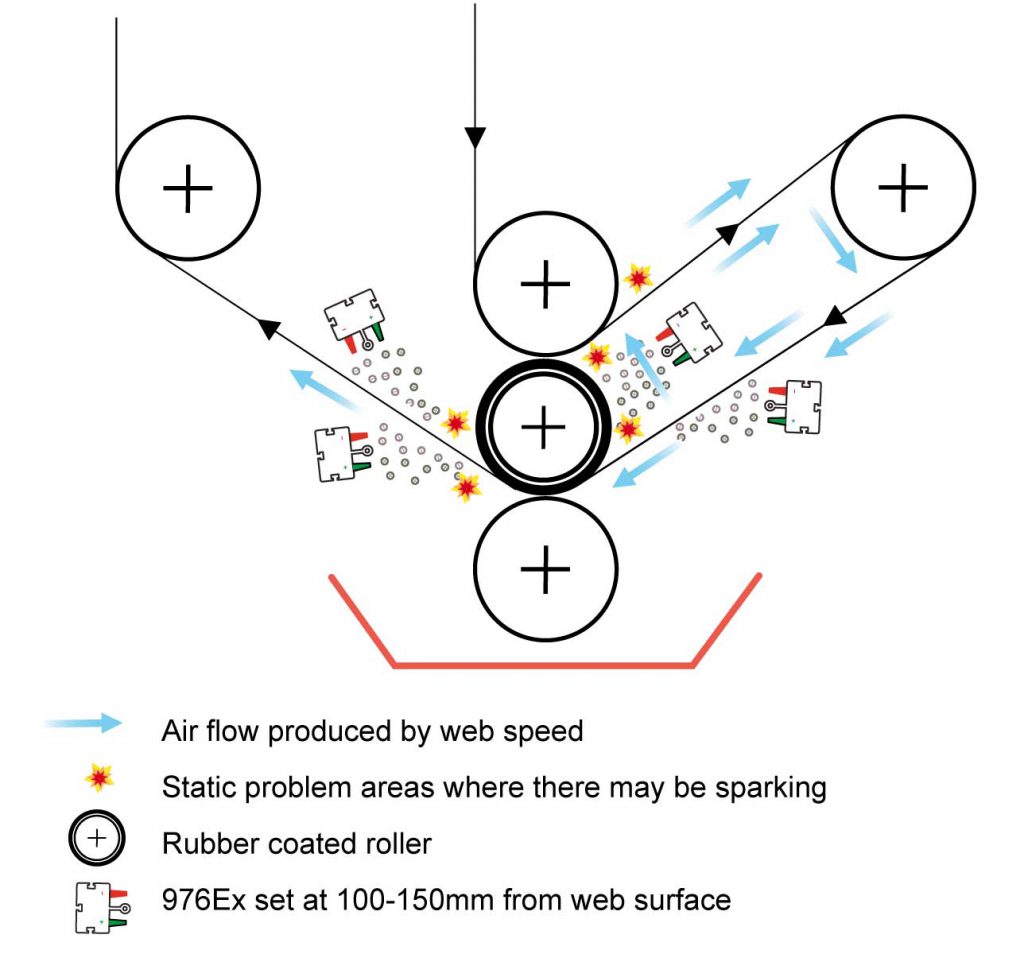

Solvent-based coating processes can present high risks due to the generation of high electrostatic charges on the substrate and rubber coated machine rollers. Subsequent electrostatic discharge can ignite the solvent rich environment, leading to:

- Fire outbreaks

- Machine damage

- Loss of production

- Health & safety issues

Solution

Only static control devices that meet stringent ATEX requirements can be installed in classified hazardous environments. Meech model 976Ex long range pulsed DC systems offer a proven solution to potential static discharge problems on high speed solvent-based printing and coating lines.

The 976Ex is certified by Baseefa to comply with Article 9 of the Council Directive 94/9/EC (ATEX) under EC Type Examination Certificate No Baseefa04ATEX0348X.

Download- Related Products