Hot melt labelling

PROBLEM

Label stock entering into the label applicator can become highly charged on the lead and trail ends of the label.

This will result in:

- The label wrapping round the rotary knife

- Glue being applied to the vacuum drum

- Labels sticking to the vacuum drum and not the bottles

SOLUTION

Neutralising the web prior to entry to the applicator, will reduce the charges to prevent mis-feeding and subsequent line stoppages.

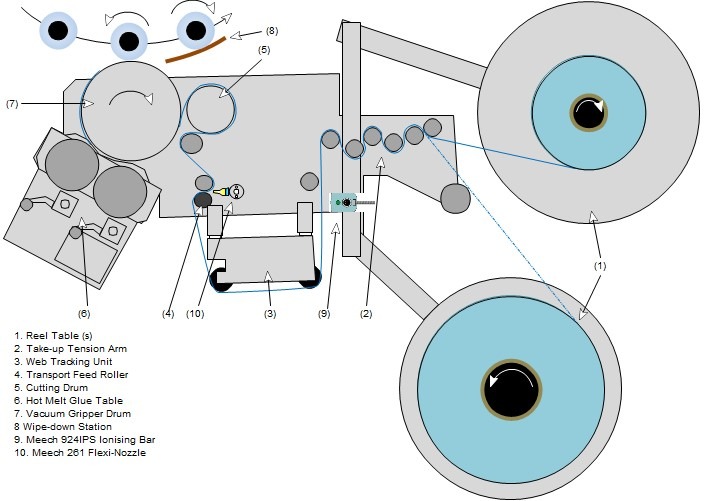

- The drawing shows (9) 924IPS bars mounted before the web guide.

- (10) a 261-flexi nozzle at the exit from the nip rollers prior to the cutting drum

- Related Products