Tool Charging

IN-MOULD LABELLING PROBLEM

In-mould labelling tool technology such as conductive foam, conductive resin, pinning heads & pre-charging systems suffer with some or all the following:

- Short mandrel working life

- High manufacturing costs

- Long manufacturing lead times

- High scrap rates

- Product contamination

- High voltage cable damage

SOLUTION

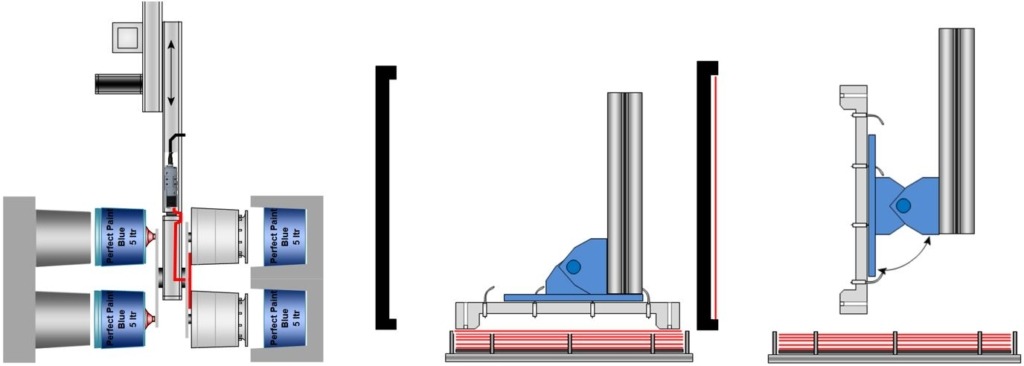

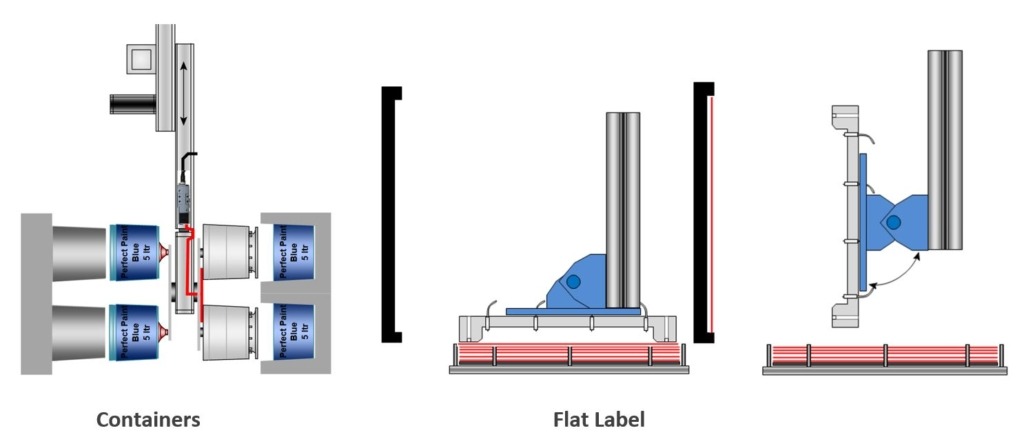

Mount the Meech IML Static Generator on the robot arm and remove high voltage cables in the cable track, which can then lay next to low voltage signal wiring. Meech mandrel designs allow resistively coupled pins to charge the label as the mandrel exits the cavity, producing total surface charging of the label, ensuring precise label placement. The Hydra charging cycle speeds up the cycle time, whilst reducing the risk of producing poor quality products.

Download- Related Products