Injection moulding-Master batch sticking

PROBLEM

During the injection moulding process, masterbatch is added to the raw material. Static charges on the masterbatch will cause it to stick to the walls of the blender resulting in colour variances in the finished product.

Controlling static charges are key to producing quality product to suit the customer need.

SOLUTION

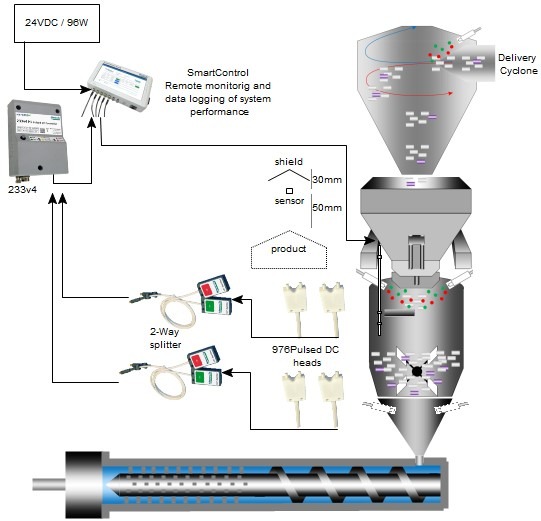

- Static control added to the Cyclone allows dust to be extracted from the raw material with the air.

- Static control added to the hopper blender will control static charges on the masterbatch and raw material as it is blended delivered to the extruder.

- A feedback sensor above the product level in the blender can monitor and auto adjust the ionisation to manage static levels.

- SmartContol links the sensors and ionisers data logging performance of all equipment connected to it, ensuring optimum performance and compliance is maintained.

- Related Products