Plastic Conveying – Flowtube

PROBLEM

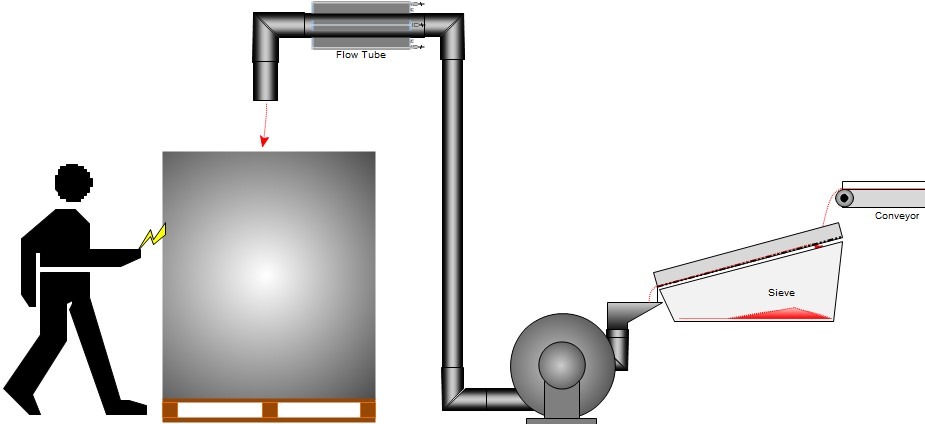

Static charges are generated by the frictional forces during the conveying of plastics. When delivered into hoppers, these static charges can build to very high levels. Operators needing to handle the hoppers are at risk of static discharges which can be high enough to result in health and safety non-compliance.

Controlling the static charges are key to keeping the operator safe.

SOLUTION

Where ducting diameters are ≥ 200mm using a Meech ionising flow tube, ionisation is introduced into the airflow removing the static charges to ensure a safe working area.

The ionising flow tube is powered remotely by an AC controller.

Download- Related Products