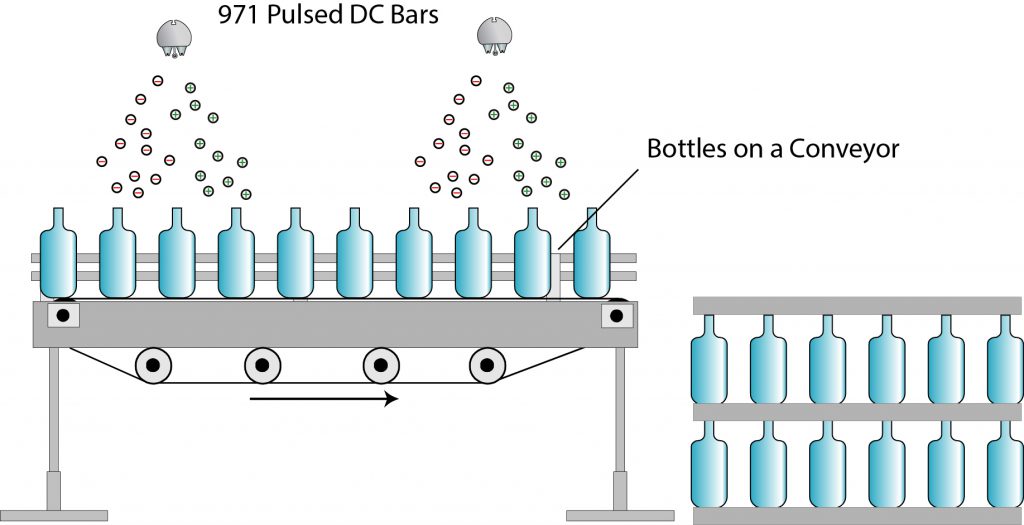

Static Control During Conveying & Palletising Of Bottles

Problem

Blown bottles exiting a blow moulding machine are highly charged with static.

This will cause the bottles to fall over on the conveyor or collation table, resulting in blockages and damage to product and attraction of contamination.

Solution

Neutralising the bottles exiting the conveyor using a 971 system, whilst also controlling the residual and regenerating charges as the bottles cool on the collation table also using a 971 system, provides an effective solution for maximising production and minimising wastage.

Download- Related Products