Wicketer bag making

PROBLEM

During the bag making process, there are many problems caused by static charges, or aided by applying a static charge.

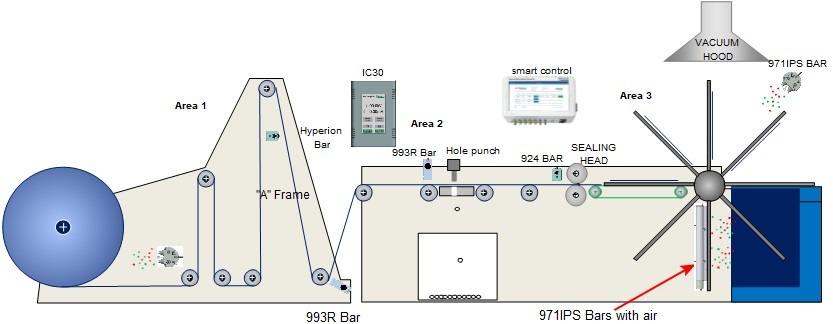

Area 1: Static control

Static charges generated during unwinding materials will attract contamination. This has a major impact for food packaging. The web is then folded over the “A” frame trapping static charges inside the two layers.

Area 2: Static Generation

The addition of a gusset to the bag needs the material to be held in place to prevent the guset from moving out of alignment.

Where a reinforcing strip of plastic is required to strengthen the handle section of the bag, this needs to be held in position.

The punching of a handle through the material can cause the material to separate and stick to the punch.

Area 3: Static control

Static charges in the material need to be removed prior to the sealing heads to maximise the static control on the final product.

After sealing controlling static charges on the outside of the bag during transfer and pegging is required to allow them to sit flush on the pegs and not be ripped off by the rotating arms.

Not controlling the static charges through the production process, will cause customer issues as the bags will fail to open properly.

SOLUTION

Many antistatic systems have been evaluated in this application. Although adequate for slow machines, they are not fully effective on the newer high-speed machines. To allow maximum efficiency the recommended static control system below will optimise the production process:

Area 1: Static control

The use of a long-range high powered IPS bar will prevent the attraction of contamination to the material.

Using a short range high powered IPS bar prior to folding ensures the charges are removed from the inside face of the web.

Area 2: Static Generation

Applying a static charge to bond only the gusset in position, will prevent material movement and alignment issues.

Applying a static charge to reinforcing strip and web will temporarily lock the two layers into position.

Applying a static charge to punch area of the material temporarily bonds the material together, preventing separation of the layers.

Area 3: Static control

The use of a high-powered short range IPS bar delivers static control though the material to the inner layers.

Two Meech long-range high powered IPS bar are required during the wicketing process. The first bar removes charges from the bags as they pass on the wicketing arms. The second uses a small quantity of compressed air, blowing ionisation continuously over the bags on the pegs, preventing charges being regenerated during the application of the next bag onto the pegs.

Note: the use of SmartControl to monitor ionisers performance in this application is a major advantage as bar condition is a major issue due to plastic vapours contamination of the bars reducing the performance. Without being able to monitor performance loss of production is the first identifier of issues.

SmartControl allows maintenance to be scheduled without effecting productivity and machine unexpected downtime.

Download

- Related Products