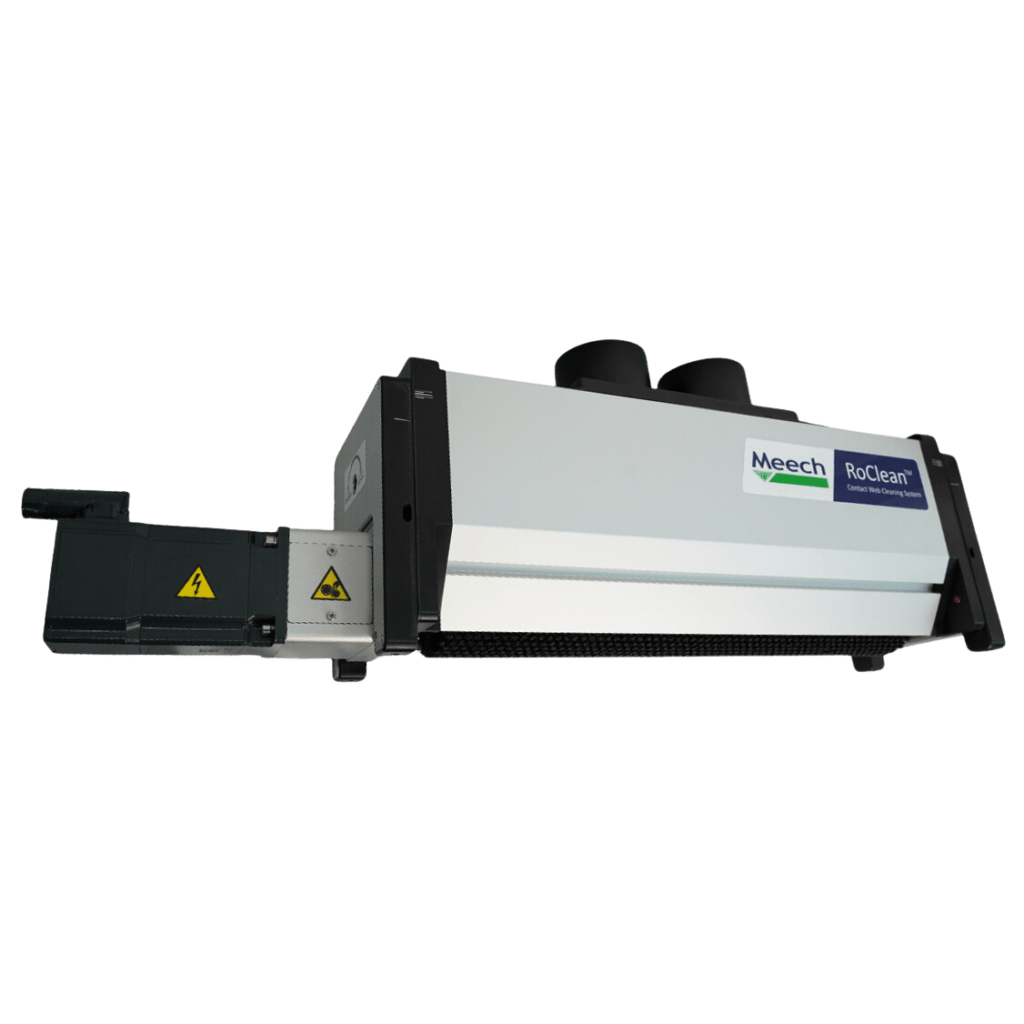

RoClean™ Contact Web Cleaner

Product Code: RoClean

RoClean is the latest contact web cleaner from Meech, delivering excellent surface cleaning results for the battery film manufacturing industry as well as other applications demanding exceptional cleaning standards.

RoClean effectively cleans the web surface through the use of both static control and an efficient bristle roller brush. The 924IPS ionising bars neutralise the static charges on the web, releasing the contaminants, whilst the bristle brush rollers rotate at speed in order to sweep clean the surface. The contamination is then immediately vacuumed into the AHU filtration unit to avoid recontamination of the surface.

As RoClean is positioned above or below a guide roller on the web production line, it avoids all issues of tension in order to provide a high level of surface cleaning. For double-sided cleaning, two units may be used consecutively on the line.

In order to meet the varying needs of applications, RoClean brush rollers are interchangeable. This gives the ability to use the most suitable bristle media to meet the needs of the application and the material, be it a delicate surface or a more demanding application. This makes the RoClean versatile to a number of installations and changing production lines.

DownloadFeatures & Benefits

The latest DC static control technology is integrated within the design of the RoClean. This neutralises the web surface as it enters and exits the RoClean, reducing the risk of re-contaminating the web.

RoClean is flexible to work with various web thicknesses, making it suitable for a number of applications.

This ensures that there is minimum disruption of the production line, maintaining high levels of efficiency.

The ability to quickly change the rotary brush on the RoClean is achieved by access from both ends of the unit. This leads to reduced maintenance downtime and greater efficiency.

Ensuring optimum cleaning results.

The roller speed can be adjusted and maintained through the touchscreen input available on the AHUv3. (This is only available when the control panel is included with the system).

Designed to work in clean and dry-room environments. (Definition of drying room conditions: Purity class according to ISO 14644-1: ISO 7, Ambient Temperature +20 °C ± 2 °C, Dew Point -55 °C ± 2 °C, Room Humidity: <1%).

Keeps operating costs to a minimum.

Technical Characteristics

1300mm

80mm

2 x M8 mounting holes positioned at each end of the RoClean

Must Haves

AHUv3 Mini – 1 Pump

AHUv3 Mini – 1 Pump

Product Code: AHUv3 Mini

The AHUv3 Mini – 1 Pump provides the positive pressure and vacuum pressure airflows and houses the system filters.

AHUv3 Compact – 2 Pump

AHUv3 Compact – 2 Pump

Product Code: AHUv3 Compact

The AHUv3 Compact provides the positive pressure and vacuum pressure airflows and houses the system filters. The AHUv3 Compact is a 2 pump unit designed predominantly for narrow web applications of up to 600mm.

AHUv3 Standard – 3 Pump or 6 Pump

AHUv3 Standard – 3 Pump or 6 Pump

Product Code: AHUv3

The AHUv3 provides the positive pressure and vacuum pressure airflows and houses the system filters. There are 2 models available, a 3 pump unit and a 6 pump unit. For applications where a higher volume capacity is required the 6 pump unit can be used.