Injection moulding – swarf control

PROBLEM

Static charges on small injection moulded components may also contain small plastic particles.

- These particles may stick and damage the mould tool.

- Contaminate the conveyor to cross-contaminate later produced components

- Attraction of airborne contamination

- Products sticking to conveyor to drop on the floor under the machine

Controlling static charges are key to producing quality product to suit the customer need.

SOLUTION

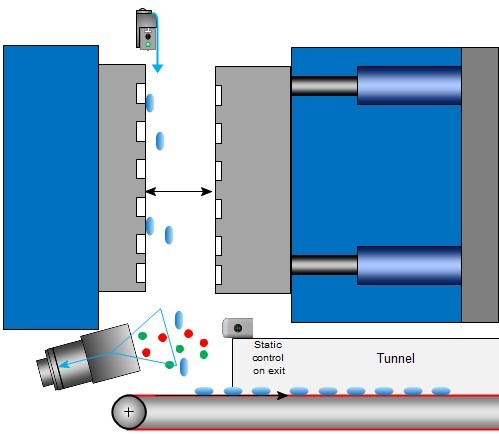

- Positioning a Meech Hyperion air curtain over the top of the tool to deliver ionised air down the tool face, neutralising charged components to prevent attraction.

- Positioning a hygienic bar below the tool face neutralises the conveyor belt and products as the fall.

- A Meech air amplifier can provide a negative airflow to capture contamination and be safely ducted away to a filtration bag.

Download

- Related Products