SELECTING THE RIGHT

WEB CLEANER

· What is Web Cleaning and how do i select the right one? ·

Web cleaning is the process of removing contaminants or unwanted substances from a continuous web of material as it moves through industrial processes. It is commonly used in industries such as printing, coating, laminating and converting , as well as many other industries where a continuous web of material is processed. Typical materials include packaging, paper, and films.

The purpose of web cleaning is to ensure consistent product quality, reduce defects, and minimise machinery maintenance, which in turn helps manufacturers maintain high production efficiency, reduce waste, and deliver reliable, high-quality products to their customers.

Selecting the right web cleaner starts with understanding your application and the materials you work with. The following page will guide you through the key factors to consider when choosing the appropriate web cleaning solution.

· IDENTIFYING THE CONTAMINATION ·

Different types of contamination can reduce product quality and production efficiency across industries, reach the web in various ways and require different technologies to prevent them. However, some contaminants are more common than others. Examples include:

DUST AND DEBRIS

Dust and debris are one of the most common types of contamination. They may already be present on the web material when received from the supplier or come from ambient airborne particles, such as those generated on knives or blades during processes like slitting, which can break away and fall onto the web.

FIBRES AND LINT

Fibres and lint are most common on nonwoven, textile, and glass fibre materials. They can accumulate on the web during production, embed themselves deep into the material and subsequently cause defects in later stages of the process.

DIE CUT CHADS

This type of contaminant is often found in paper production. Die cut chads from the cutting machine can attach to the web and contaminate the material. If left on the web, these contaminants can interfere with machinery and cause marks or defects on the finished product.

HAIR AND INSECTS

Hair and insects can contaminate the web during production and handling. These contaminants can become trapped on the material, leading to visible defects and hygiene issues, depending on the application.

· DETERMINE THE MATERIAL ·

Understanding the material being processed is a key step in selecting the right web cleaner. Factors such as sensitivity to contact influences the type of cleaning technology that will be most effective.

Common materials include film, paper, nonwovens, textiles and laminate. By identifying the material, manufacturers can ensure the cleaning solution is tailored to the application. For example:

DELICATE FILMS OR LCD SCREENS

Sensitive materials such as delicate films and LCD screens may require non-contact cleaning to avoid damage.

TEXTILES

Lint and fibres can become trapped deep within the material, so may require vacuum technology to remove efficiently.

PAPER, SOLID BOARD AND CORRUGATED BOARD

Paper, solid board and corrugated board can generally tolerate contact cleaning methods.

· UNDERSTANDING WEB SPEED, WIDTH AND TENSION ·

The web’s width, speed and tension are key factors when selecting the right web cleaner, as each influences how contaminants can be removed.

WEB SPEED

The speed of the web is an important factor because it affects the thickness of the boundary layer – a layer of air that forms along the surface of the moving web. This layer acts as a barrier between contaminants and the web cleaner, allowing particles to remain on the web if not removed effectively. On a slow-moving web, the boundary layer is thin, but as the web speed increases, it becomes thicker, making it more difficult to remove dust, fibres and other particles.

Each Meech system uses a tailored cleaning technology to fully break through the boundary layer, ensuring excellent contamination removal regardless of web speed.

WEB WIDTH AND ACCESSIBILITY

The width of the web determines the size of the cleaning system required.

It is also important to consider the space available for the cleaning head and accessibility to it. Meech web cleaners are designed to be compact, allowing them to fit most presses and production lines, even in areas with restricted space. Careful planning of installation location ensures it can be accessed without disrupting production.

Web width, combined with available space and accessibility all influence the choice of cleaning technology.

WEB TENSION

Web tension is another critical factor, as different webs run at different tension levels. All Meech web cleaners can operate on high-tension webs (up to 40 Nm). For lower-tension webs Meech offers specially designed solutions such as the CyClean-R and Ro-Clean. These systems can be installed over a guide roller, bypassing tension challenges.

WHAT ARE THE ADVANTAGES OF WEB CLEANING?

Contaminants on webs and substrates can reduce product quality and production efficiency. Explore key advantages of different web cleaning technologies.

IMPROVE PRODUCT QUALITY

Keeping substrates and web materials clean by removing dust and contaminants enhances product quality, producing cleaner, more consistent finished goods.

MINIMISE MACHINE DOWNTIME

Contaminants damage webs and machinery. Clean webs reduce machine stress, lower maintenance needs, extend equipment life and cuts costs.

INCREASE PRODUCTIVITY

Clean materials and substrates reduce downtime, boost productivity, extend machine life, and improve overall operational efficiency.

REDUCE

WASTE

When a product fails to meet quality standards, it creates waste. Investing in a web cleaner reduces defects, minimises waste and saves money.

CUSTOMER SATISFACTION

Producing high-quality, defect-free products leads to happier customers, helping to build a reliable, high-quality reputation.

· OUR ·

web cleaning SOLUTIONS

Now that we have explained how to understand your application, we can introduce our range of contact and non-contact web cleaning systems.

· CONTACT ·

Our contact web cleaners make direct contact with the material. They can clean one or both sides of the web and are effective for applications where contact won’t damage the material. They use tacky roller, rotary brush or vacuum technology and all incorporate static control to neutralise static charges, removing dust and preventing recontamination.

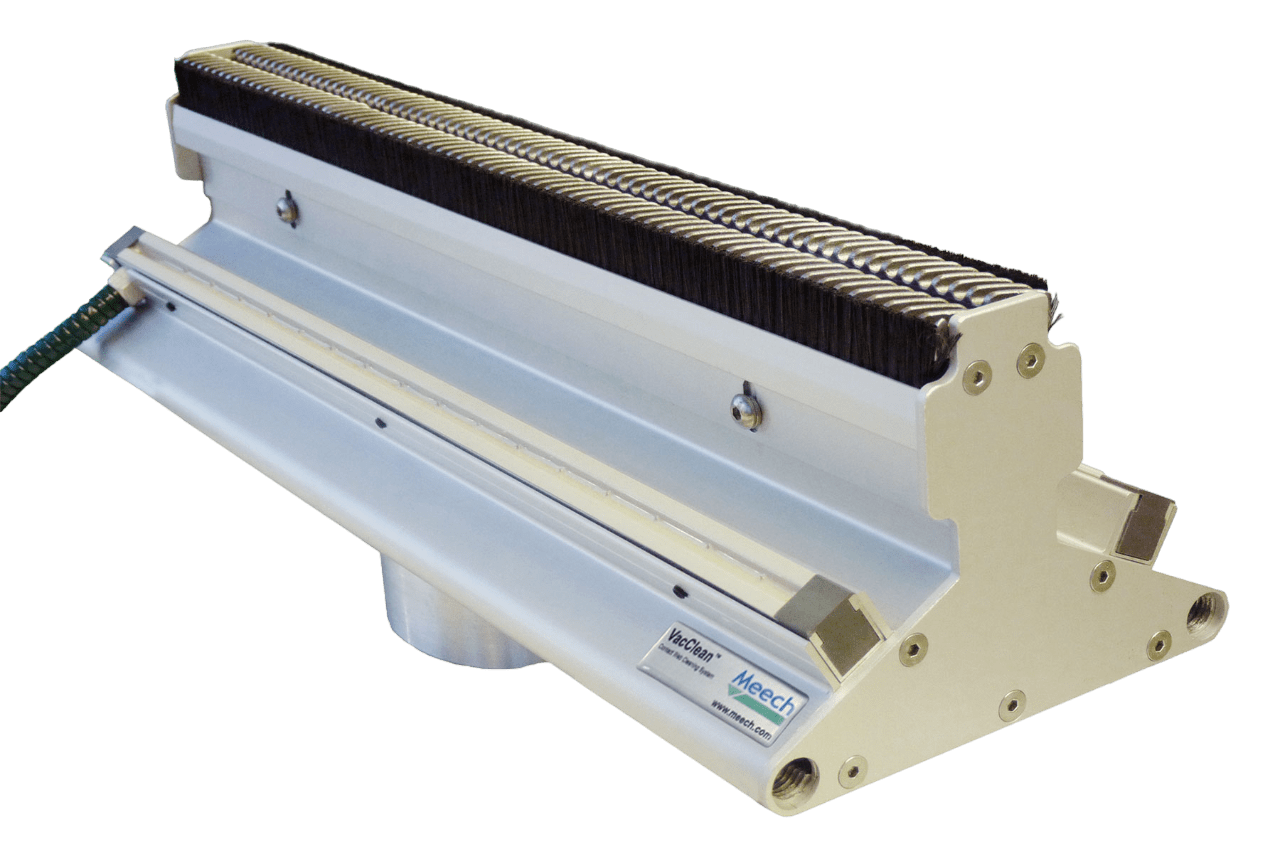

VacClean™ Web Cleaning System

For contact cleaning on high-speed webs using vacuum technology. Removes particles as small as 0.4 micron and is optimal for fibrous materials.

TakClean™ Web Cleaning System

For contact cleaning on narrow webs using adhesive and tacky roller technology. Removes particles as small as 0.5 micron and its smart design allows fast roll changing.

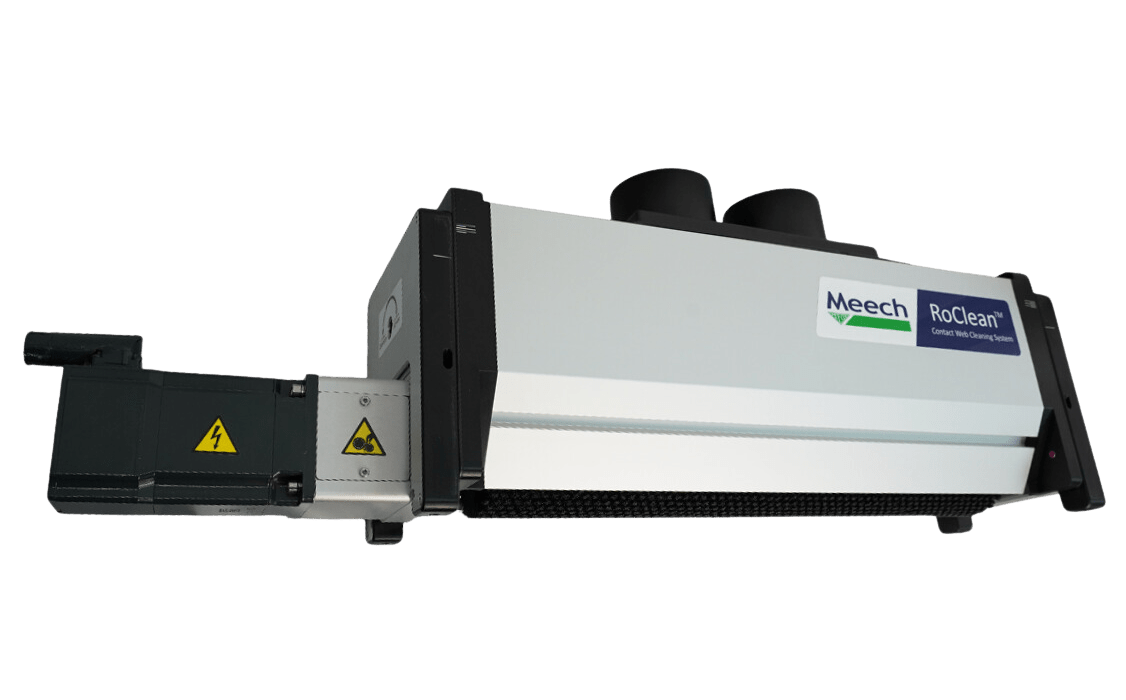

RoClean™ Web Cleaning System

For contact cleaning on low-tension webs using rotary brush and airflow combination technology. Removes semi-bonded particles as small as 0.3 micron & features a highly rigid, compact design.

· NON-CONTACT ·

For more sensitive substrates and web materials, non-contact web cleaning is the best option. As the name suggests, the material does not come into contact with the web cleaner. Instead, our non-contact web cleaners use powerful airflow and static control technology to remove and collect dust and other contaminants from the substrates.

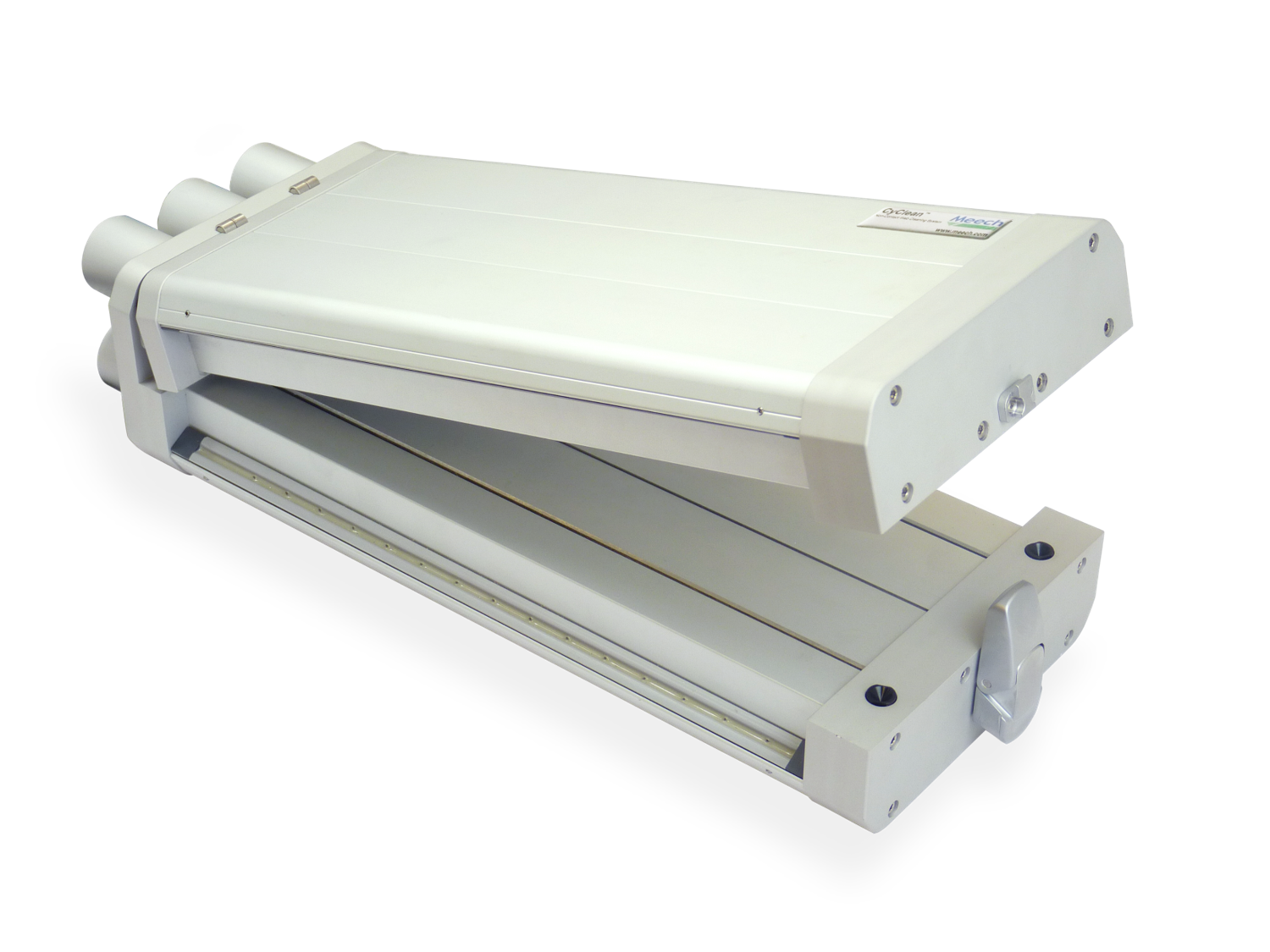

CyClean™ Web Cleaning System

For cleaning on delicate materials using airflow combination technology. Compact in design for flexible positioning and removes particles as small as 1 micron.

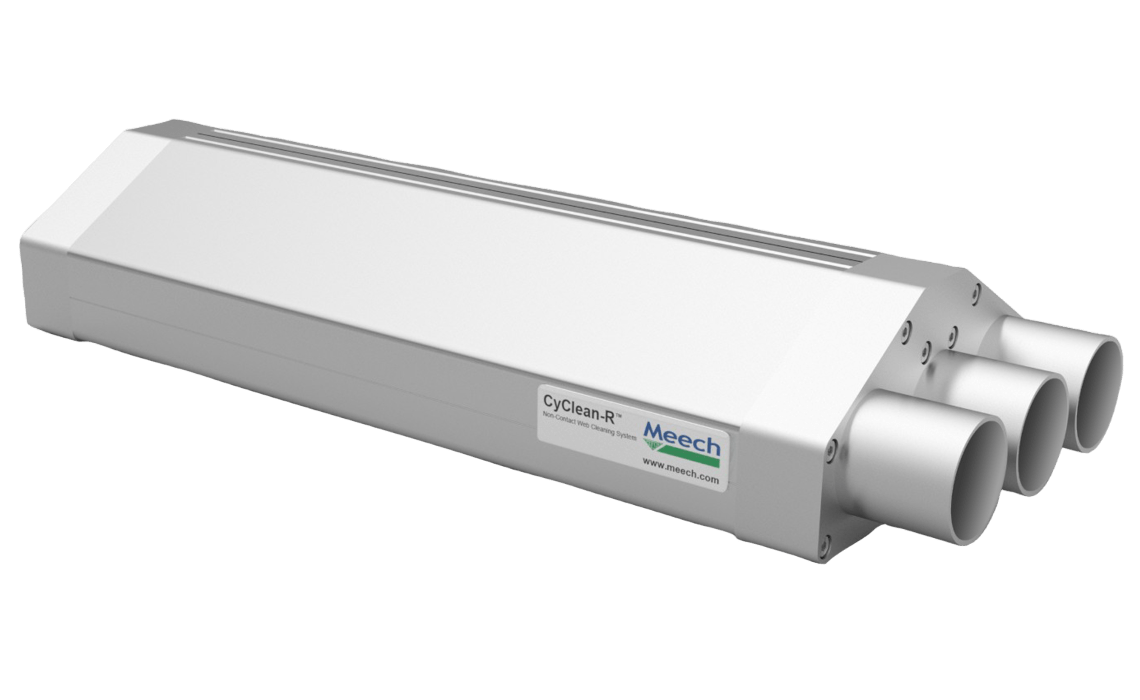

CyClean™-R Web Cleaning System

For cleaning on delicate, low-tension webs that sit around a rollers using airflow combination technology. Removes particles as small as 0.5 micron and available in narrow, mid & wide web widths.

WHAT ARE THE RISKS OF NO WEB CLEANING?

It may not seem obvious.. but leaving dust and other particles on web material can significantly impact the quality of the final product. To highlight this, we have outlined the key risks of not using a web cleaner.

COMPROMISED PRINTING QUALITY

Dust particles on printing substrates can interfere with the material causing defects, streaks and blemishes, negatively affecting images, graphics and text.

INCONSISTENT

COLOURS

Even the smallest dust particles can alter colour. This causes inconsistences that result in increased waste and reduces overall production efficiency.

COATING AND LAMINATION ISSUES

Dust on substrates disrupts the bonding quality of coatings, laminates and adhesives causing poor adhesion or delamination and compromising the final product.

POOR SUBSTRATE ADHESION

Dust on substrates interferes with the adhesion of inks and other adhesives, causing label or packaging failure and requiring additional quality control checks.