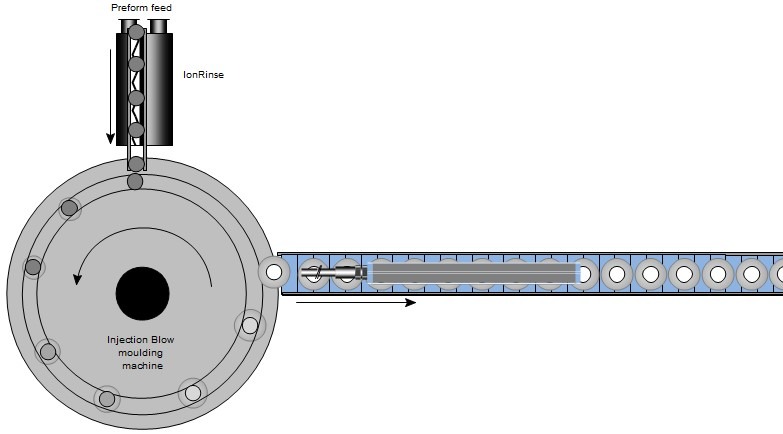

Ionrinse blown preform bottles

PROBLEM

- Static charges generated on preforms during the injection moulding process attracts contamination to the preform during storage, transfer and feeding into the blow moulding machine.

- During blow moulding the contamination becomes part of the container trapping and contamination or bacteria within the container structure.

- After blow moulding static charges on the finished container can attract more contamination to the product, cause containers to stick together on the conveyor or cause them to fall over jamming the conveyor.

SOLUTION

- Prior to the preform entering the blow moulding machine, an IonRinse injects ionised air in a wave form into the preform, neutralising the static charges allowing the vacuum to extract the contamination and trap it within the F8 filter inside the AHU.

- Installing a Meech Hyperion bar over the conveyor, neutralises the static charges generated during blow moulding, reducing the risk of contamination attraction and conveyor jams which cause machine downtime.

Download

- Related Products