Packaging

Contamination removal in packaging manufacture

The Packaging industry is a vital part of the modern world and it has widespread global impact. The sector is vast, serving end markets with an array of material types. From low-cost plastic bags to high end consumer packaging, food and pharmaceutical products quality and safety is of great significance.

The Packaging Market size is expected to grow from USD 1.10 trillion in 2023 to USD 1.33 trillion by 2028.

Static charges can create challenges in many areas of packaging processes.

The primary problems resulting from high level of static charges are:

- Process control & Quality problems

- Dust attraction & Contamination

- Operator shocks

Meech provides solutions for your static problems with a variety static control and the widest range of surface and web cleaning products.

Our Zero Faults Forward Approach

We have identified a number of applications within packaging manufacture that are prone to contamination on the line. By applying the right solutions at these points, you make sure there are no weak links to your production chain. We explore these below and demonstrate our solutions…

Packaging manufacture applications

It is critical that static electricity is controlled during the manufacturing of packaging. Below are some of the main areas affected by static charges during production, and our solutions to remove static charges and other contaminants:

Blister Packaging

Friction generated during the unwinding of the roll of thick plastic film creates static. These static charges attract contamination from the surrounding area onto the film. During the heating and forming of the film to produce the blisters, the contamination bonds to the plastic film, creating permanent inclusions and potential scrap.

The warm plastic generates even more static charges as it cools. This will result in further contamination or filling issues. These issues can include contamination from operators such as hair or skin, or repelling of the product, for example medical tablets or powders, during the filling of the blister.

Rolls of material which are purchased and found to be already contaminated will need to be cleaned. A web cleaner, such as a Meech Non-Contact CyClean, mounted prior to thermoforming is ideal for removing and capturing contamination safely. An ionising air curtain such as a 957 or 959IPS will remove the contamination but will not capture it. However, static control products can be the solution where budget is limited or quality is not imperative.

Controlling static charges during product packing will allow the product and clean blister packaging material to come together, preventing product misbehaviour and inclusion of contamination. This can be done using a long range ionising bar such as a Meech 960IPS or 971IPS.

Bottle Labelling

Bottle labelling. The buildup of static charge on the label web or on the plastic bottles will result in poor label feeding or incorrect lable placement. These problems can result in the mislabelling of bottles, slower production speeds and a higher defect rate.

Meech Ionising equipment can help to overcome these problems. View our Hyperion range of ionising bars HERE to find out more.

IML Decoration Of Plastic Moulds Using Static Pinning

During in-mould labelling processes, the label must be placed and held in an accurate position inside the mould tool. This can be complicated and unreliable using tabs or recesses. Movement of the label will lead to the product being rejected. Pinning the label in-situ using static electricity, avoids complicated design issues and provides an excellent temporary bond to fix the label in place during the moulding process. The label is picked up by the robot arm and then it is either passed over a static charging bar and placed into the tool, or is moved into the tool and ‘pinned’ directly on to the surface of the tool. Both these processes can also be manual. Once the label is stuck to the tool surface the robot arm retracts, the mould closes and plastic is injected to form a plastic container complete with label.

Meech IML Hydra Pinning Systems and Pinning Heads are ideal to support on this application.

Thermoforming

Thermoforming. Sheet materials need to be free of contamination and plastic swarf prior to entry to the thermoforming machine. Failure to manage material cleanliness will result in inclusions embedded in the finished product. Large sheets can be cleaned using a Meech JetStream Ionising Air Knife System, while smaller sheets could use a Meech 959IPS air curtain or Meech 251 ionising gun. Charges generated during thermoforming may result in further contamination or operator shocks during handling.

Package Printing

Package printing. Dirty webs can cause poor print quality. Within the consumer packaging poor print quality will cause high reject rates, excessive downtime, therefore will increase manufacturing costs. Whichever the material in hand

Meech can offer the suitable solution with a big range of contact and non-contact web cleaners, which you can view online HERE.

Form, Fill and Seal Operations

Form, Fill and Seal operations. For example in powder filling processes, static charges are generated on the powder as it is delivered into the filling head, which causes the powder to be attracted to the rim of the bottle and the dust is repelled back onto the auger spout.

Meech Ionising nozzle range can support resolving these challenges. View our range of AC and DC Ionising equipment online HERE for more information.

* All drawings are for illustrative purposes only. The position of the static control and web cleaning solutions most suitable for your process will depend on certain factors of your application.

Web Cleaning Solutions

Meech is a leading Web Cleaning manufacturer with a comprehensive range of four systems. Each system is based on a different cleaning principle, this uniquely allows us to provide our customers with a system best suited for their application. All Meech systems incorporate the latest shockless AC static control bars as standard which is crucial for comprehensive contamination removal. Meech has more than 200 successful web cleaning installations in a range of industries including Packaging, Printing and Converting.

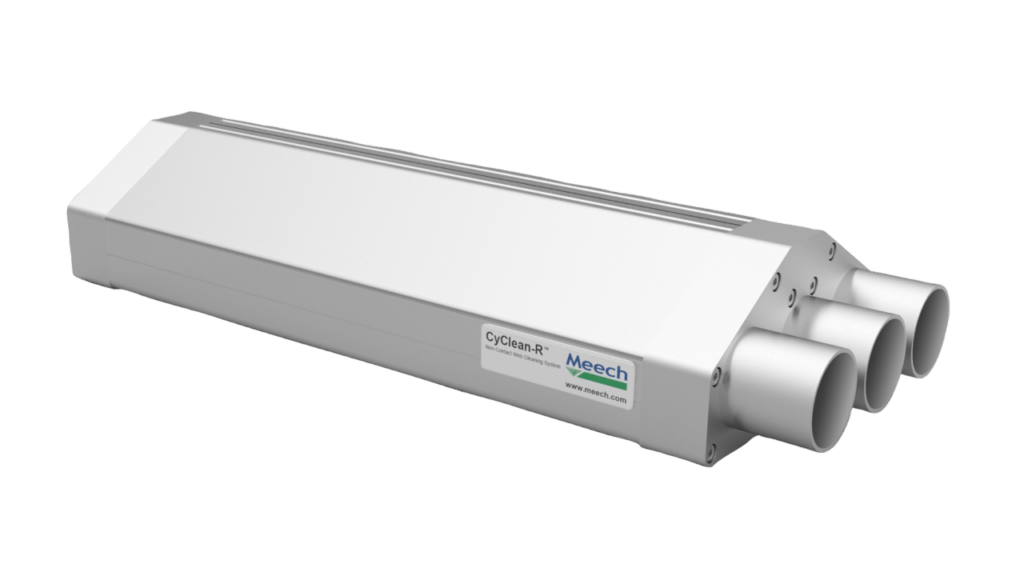

Meech CyClean™ has been designed in response to demand for a compact, high performance, non-contact web cleaner.

Through the application of advanced computational fluid dynamics, CyClean removes and extracts contamination below 1 micron.

The CyClean-R provides a specialised solution for low-tension web cleaning.

The CyClean-R is designed to be positioned on the roller, where the web tension is at its highest, therefore bypassing the issues of low tension and still delivering excellent surface cleaning.

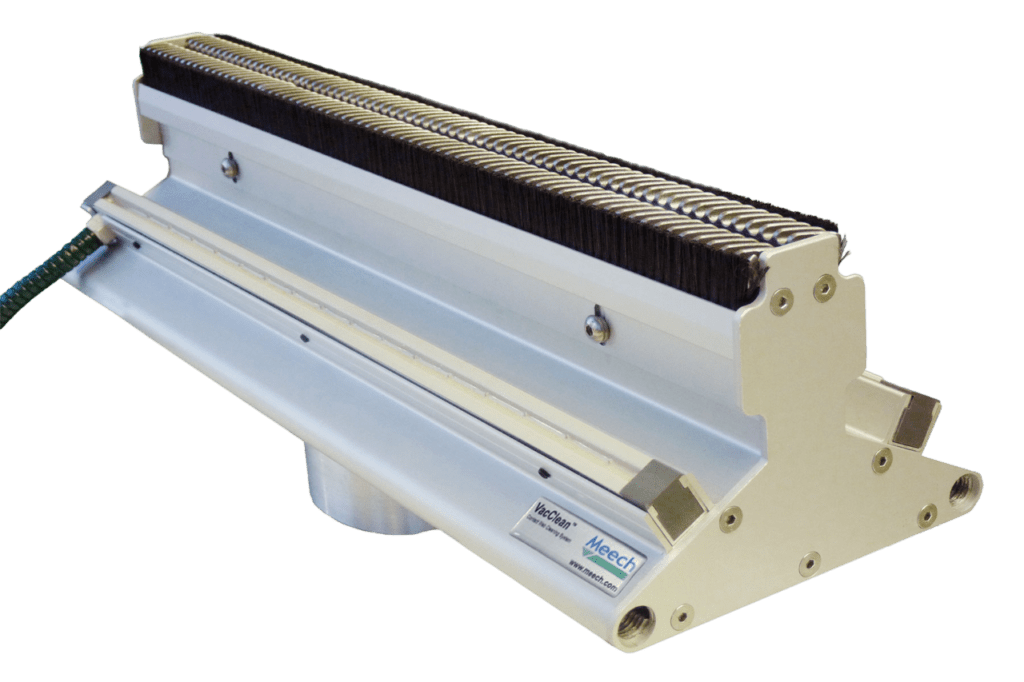

The Meech VacClean™ contact web cleaning system is an evolution of Meech’s successful Tornado system, of which there are hundreds of installations globally. VacClean systems incorporate an enhanced contact cleaning manifold with either an Air Handling Unit (AHU) or vacuum fan unit, depending on the installation environment and web width.

Static Control Solutions

Meech is a market leader in manufacturing and supplying static control products since the 1960’s; offering a wide range of electrostatic products that provide anti-static and ESD protection and measurement, static generation, electrostatic control and elimination.

SmartControl Touch is the latest innovation from Meech designed to meet the needs of modern automated industries and the growth of Industry 4.0 to achieve maximum productivity and output quality.

SmartControl Touch allows the user to monitor, control and adjust the performance of multiple connected Hyperion ionising bars and sensors via the integrated touch-screen or remotely.

Powered by 24V DC the Hyperion 924IPS is the most compact pulsed DC bar available on the market.

The 924IPS features Meech’s Ion Current Monitoring (ICM) technology, this ensures performance is maintained with local and remote alerts when the bar needs cleaning.

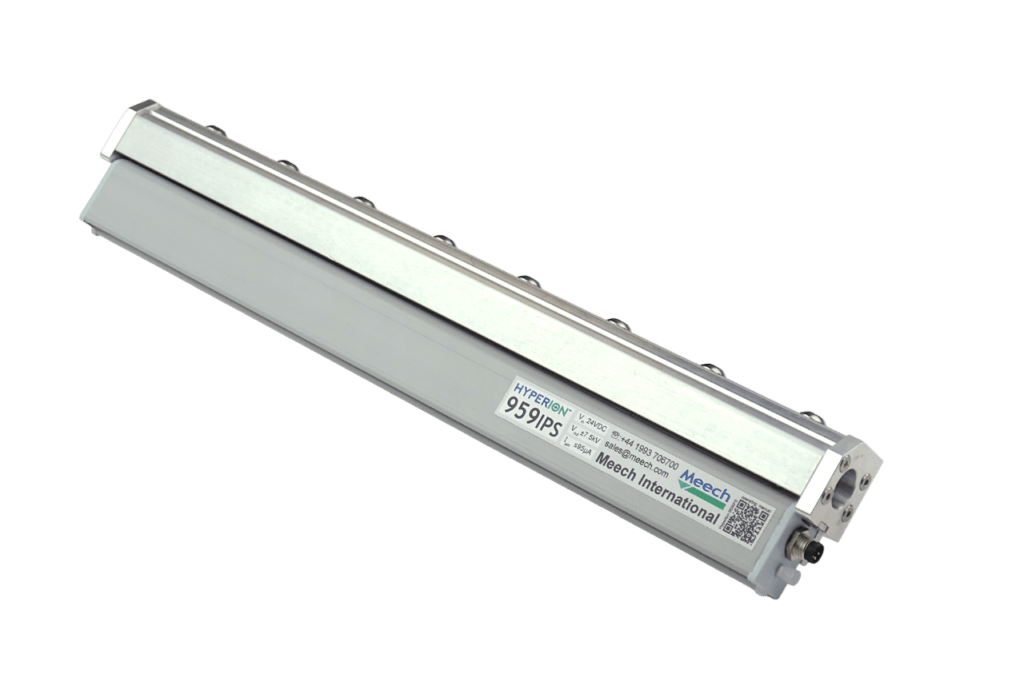

The Hyperion 959IPS ionising air curtain is an extremely versatile product that provides effective static neutralisation and dust removal.

Comprised of a Hyperion 924IPS mounted on a Meech energy saving air curtain it provides a high speed laminar sheet of ionised air.

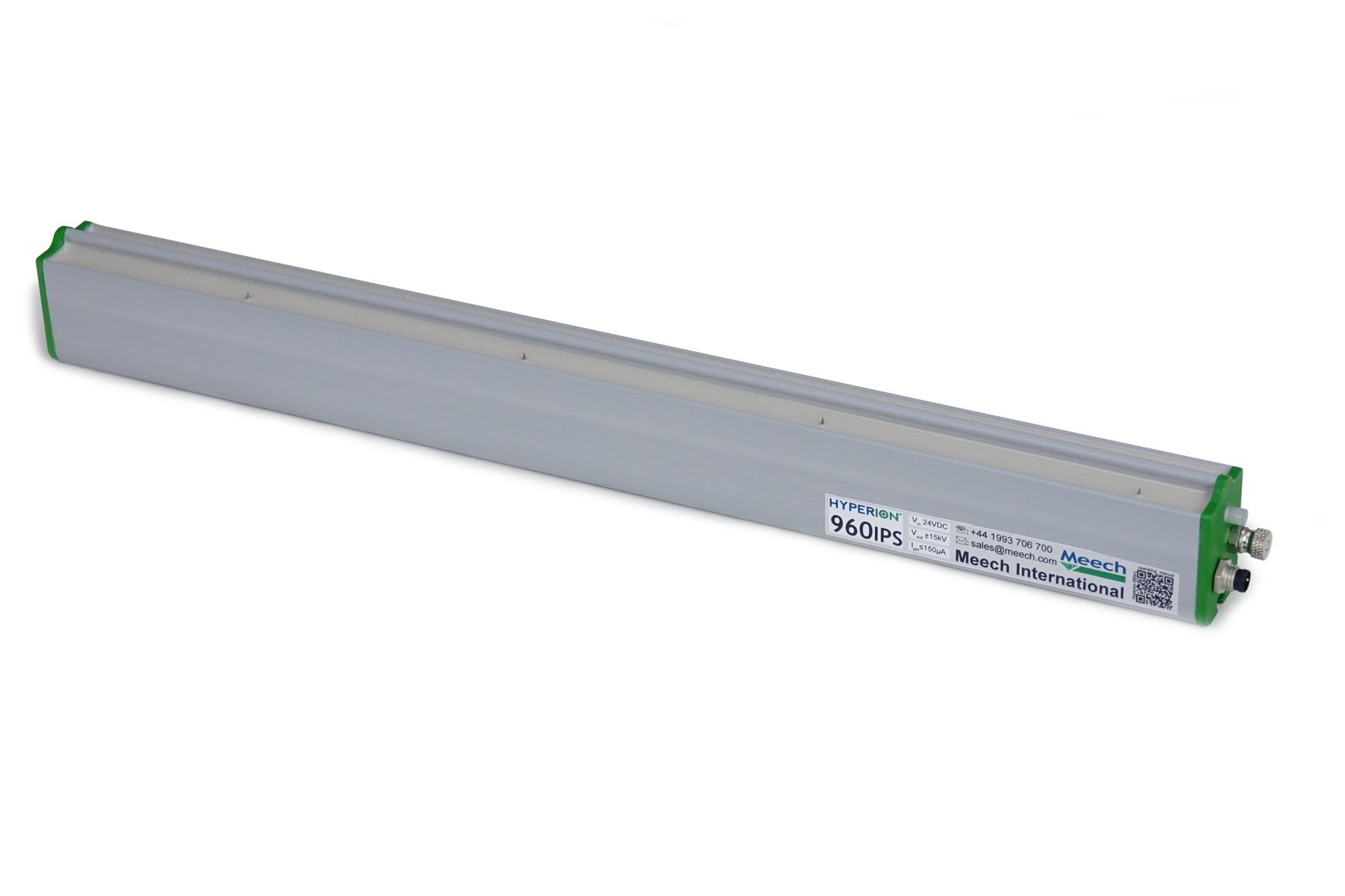

The new Hyperion 960IPS from Meech is a compact pulsed DC ionising bar with integrated high-voltage power supply (IPS). Powered by 24V DC, the 960IPS delivers powerful ionisation for mid-range applications.

The need for powerful ionisation to cope with modern fast machinery is answered by the Hyperion 960IPS. Compact dimensions of just 30mm x 45mm make it easy to install on printing and converting machinery. The 15KV pulsed DC output gives class-leading performance. The default settings will provide ideal static control on most installations with target distances from 150mm to 450 optimum performance e.g. for improving long-range performance.

Could we help improve your medical manufacturing process?