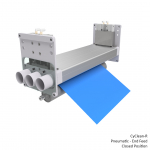

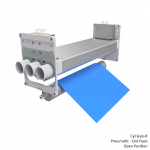

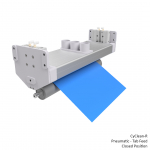

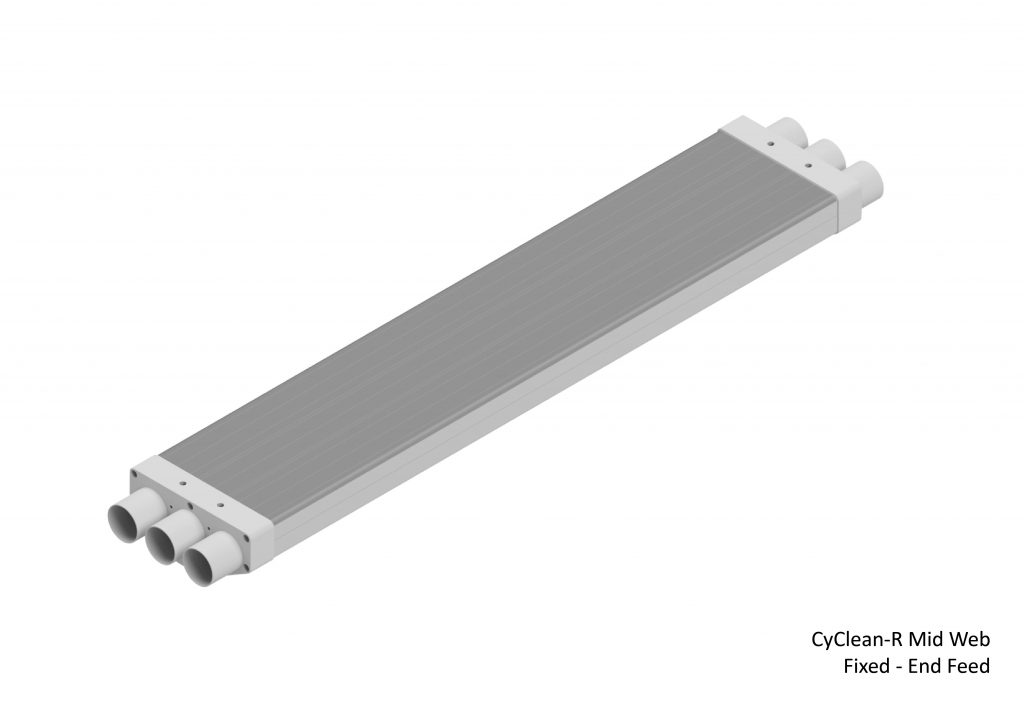

CyClean™-R Mid Web Non-Contact Web Cleaning System

Product Code: CyClean-R Mid

CyClean-R is an extension to our extremely popular CyClean non-contact web cleaning range. The CyClean-R was designed to meet the need in the market for an advanced web cleaning system that can be used on web that sits around a roller. This makes the CyClean-R ideal for use in many applications, especially those with low-tension webs.

The CyClean-R provides a specialised solution for low-tension web cleaning. The CyClean-R is designed to be positioned on the roller, where the web tension is at its highest, therefore bypassing the issues of low tension and still delivering excellent surface cleaning. It uses the engineered CyClean cleaning technique of advanced computational fluid dynamics, whilst bypassing the challenges presented by low tension webs by cleaning the web on the roller. It is supplied with the latest Hyperion 924IPS Bars offering industry-leading static elimination.

CyClean-R is available as a single-sided cleaning system, but can be offered as a double-sided cleaning configuration as an option. CyClean-R delivers consistent removal of dry, unbonded contamination from the web surface (particle removal to 0.5 micron is achievable).

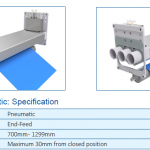

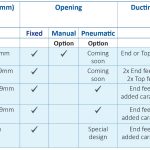

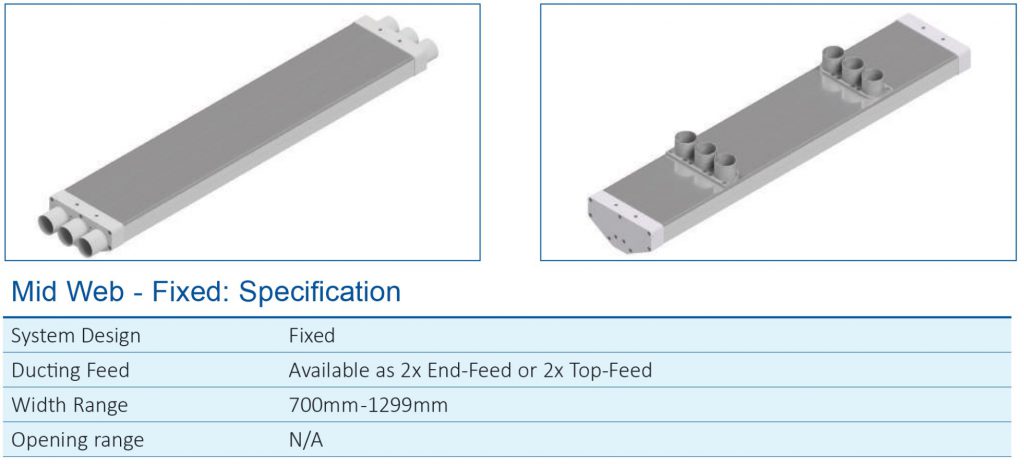

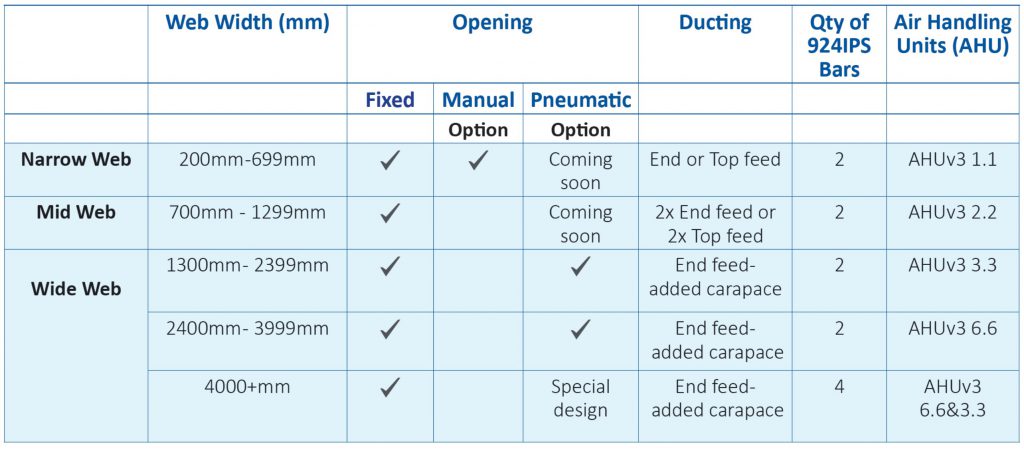

The CyClean-R for Mid Webs (200mm – 699mm) is currently available as a fixed system, with either top-feed or end-feed. If you are unsure which system would be best for you, please contact our industry experts for advice.

DownloadFeatures & Benefits

Eliminates the risk of surface damage occurring. Also ensures no interference with web tension or web tracking.

Avoids challenges presented with low web tensions and ensures effective non-contact cleaning without the danger of damaging the web. Due to the shape of the CyClean-R, the air is forced into a precise direction at extremely high velocity, enhancing the cleaning performance.

Ability to clean up to web widths between 700mm – 1299mm.Other CyClean-R models able to clean below 700mm up to 4000mm (See Narrow Web and Wide Web CyClean-R).

Space-saving design which can be installed on most machines.

Allows complete control of the balance between blow and vacuum airflows.

Reduces the frequency of required operator adjustments. Maintains optimum cleaning performance automatically.

Lower ongoing costs.

Can be installed in enclosed work areas. No health and safety issues due to low noise output.

2 x 924IPS DC Bars

Option of end-feed or top-feed spigot configurations up to 1299mm

Technical Characteristics

800mtrs/min, 2624ft/min

700mm -1299mm

Fixed position 40mm Ø OD

4x M8 x 16mm holes

Fixed

Documentation

*Access our full library of current and archived operation manuals here.

Related Products

Must Haves

AHUv3 Mini – 1 Pump

AHUv3 Mini – 1 Pump

Product Code: A-AHUV3-1PUMP

The AHUv3 Mini – 1 Pump provides the positive pressure and vacuum pressure airflows and houses the system filters.

AHUv3 Compact – 2 Pump

AHUv3 Compact – 2 Pump

Product Code: A-AHUV3-2PUMP

The AHUv3 Compact provides the positive pressure and vacuum pressure airflows and houses the system filters. The AHUv3 Compact is a 2 pump unit designed predominantly for narrow web applications of up to 600mm.

AHUv3 Standard – 3 Pump or 6 Pump

AHUv3 Standard – 3 Pump or 6 Pump

Product Code: A-AHUV3-3PUMP/6PUMP

The AHUv3 provides the positive pressure and vacuum pressure airflows and houses the system filters. There are 2 models available, a 3 pump unit and a 6 pump unit. For applications where a higher volume capacity is required the 6 pump unit can be used.